Why is there air in the reactor temperature control system?

The impurity gas in the reactor temperature control system is to increase the condensing pressure of the refrigeration system, thereby increasing the condensing temperature, increasing the exhaust temperature of the compressor, increasing the power consumption, reducing the cooling efficiency, and possibly the exhaust gas temperature is too high. The carbonization of the lubricating oil affects the lubrication effect, and in severe cases, the refrigeration compressor motor is burnt.

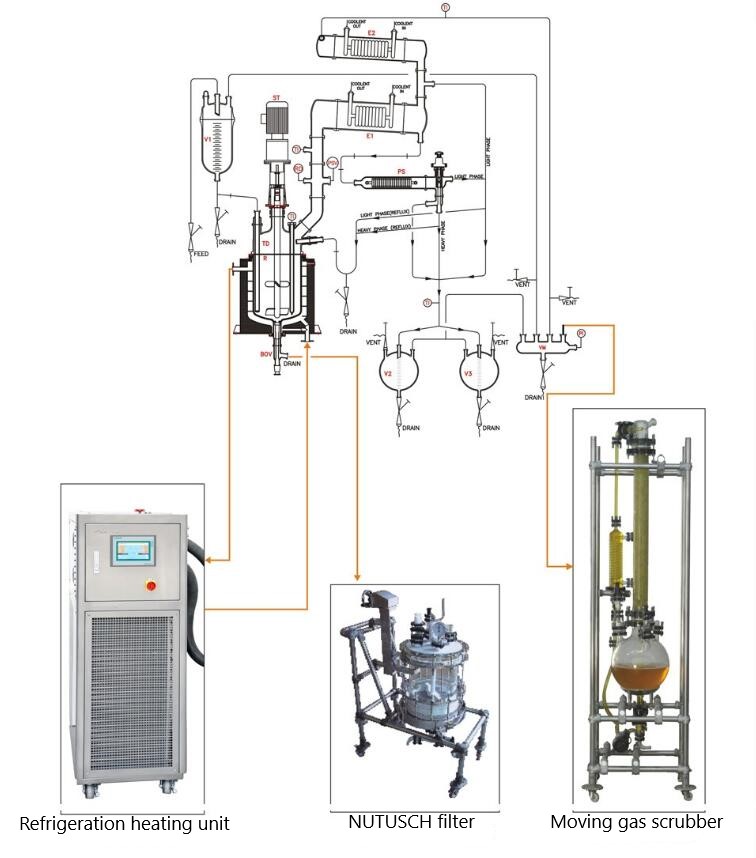

The gas generated in the reactor temperature control system may be leaking air. It may be when the refrigerant is filled or lubricated, the outside air is taken into the air, or the temperature of the reactor temperature control system is not tight enough to cause air to enter. Inside the system. In addition, gas is generated due to decomposition of the refrigerant oil, impure refrigerant, and corrosion of the metal material. Of course, Wuxi Guanya uses a fully enclosed circulation system on the reactor temperature control system to prevent this air from entering the reactor temperature control system.

In general, the gas in the reactor temperature control system is expressed in the reactor temperature control system compressor exhaust pressure and exhaust gas temperature rise, the pressure gauge pointer on the condenser (or reservoir) violently swings, the compressor The cylinder hair is hot, the condenser shell is very hot; the surface temperature of the evaporator temperature control system is unevenly frosted. When there is a large amount of gas in the reactor temperature control system, the ambient temperature cannot be lowered due to the decrease of the cooling capacity of the reactor. The machine runs for a long time, and even the high-pressure relay operates to stop the compressor.

If the reactor temperature control system has these gases, the pressure of the refrigeration system can be measured by a pressure gauge to compare with the saturation pressure at that ambient temperature. If the measured pressure is greater than the saturation pressure at ambient temperature, the system contains gas.

If the above-mentioned gases are found in the reactor temperature control system, it is necessary to eliminate these gases in time and solve the faults in time.

関連推奨品

-

反応釜温度制御システム

807反応釜温度制御システムは、反応釜内の原料の温度を正確に制御するために使用される自動化設備であり、化学、医薬、生化学、材料科学などの分野で広く使用されている。

詳細を見る -

Precautions for cooling and heating during operation of various reactors

918In many laboratories, various reaction vessels of chemical companies are indispensable reaction vessels, and its operating temperature: -80°C-250°C. The laboratory reactor works at normal temperature, and cooling water must be passed normally to a...

詳細を見る -

低温運転試験におけるチラー冷却システムの注意事項

1198There are certain differences in the use method, function, structure, etc. of different types of chiller cooling systems for low-temperature operation test. The chiller of the industrial low-temperature operation test requires heat to be generate...

詳細を見る -

化学産業における循環水チラー設備の試運転

1035After completing the installation of circulating water chillers in the chemical industry, certain debugging needs to be carried out in the early stage of operation. Only through careful debugging can we find out whether there are hidden troubles i...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー