What are the functions of the reactor temperature control system?

について reactor temperature control system is equipped with various reactors for high and low temperature reflection of liquid and solid. The temperature control system of LNEYA reactor adopts fully closed circulation pipeline, which is efficient in operation and less polluted. So, what are the advantages of the reactor temperature control system?

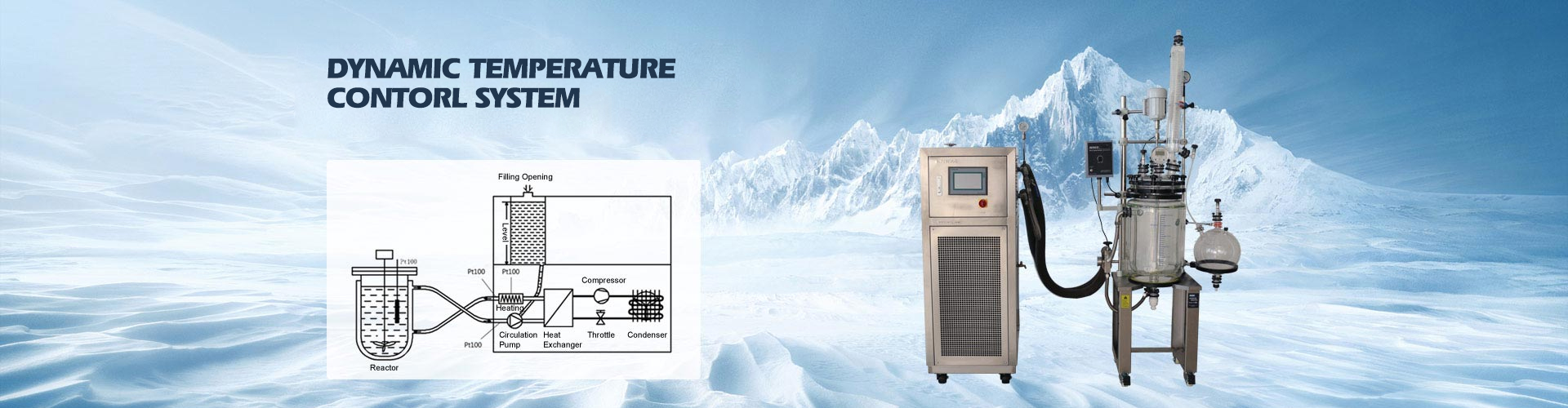

LNEYA applies the technology to the reactor temperature control equipment, which can dynamically display the operating status of each equipment in real time, including real-time data changes of raw material tank weight, feed rate of various materials, valve operation on the equipment and corresponding temperature. The data display, etc., can simulate the flow chart shape, and the image is intuitive and easy to read.

The reactor temperature control system can display the real-time curve and historical data curve of each process parameter, and compare with the set process curve to guide the production process. The displayed historical curve can be saved for more than one year, which is convenient for users to view at any time. With the various process curves and ratios of the memory in the system, it is possible to issue control requirements to the PLC at any time according to the requirements of the production process, so that the production variety and the rapid change of the production process can be completed.

In addition, the reactor temperature control system can print a variety of production and statistical reports, with a very strong management function, the actual weight of each batch and the corresponding temperature, pressure data, etc., to print the data cost Accounting. The LNEYA autoclave automatic control system can perform manual and automatic interference-free switching operations. In order to enhance the performance of the whole system without losing flexibility, the system is equipped with computer operation and can be operated by touch screen, whether manual or not. Automatic or console button operation can be implemented very conveniently.

The reactor temperature control system uses an intelligent control technology to dynamically adjust the temperature by automatically adjusting the multi-parameters of the reactor jacket cooling water and material feed rate, thus allowing various physical processes and The chemical reaction process is more efficiently controlled.

The LNEYA reactor temperature control system uses a complete safety protection device to ensure safety problems in the production process of the reactor temperature control system to a greater extent.

(This article source network, if there is infringement, please contact LNEYA to delete, thank you.)

関連推奨品

-

what are the causes of the blockage of the cooler

960The cooler is a very important part of the screw air compressor. The main function is to cool the lubricating oil of air compressor and the compressed air. If it's blocked, then the temperature will go up. A main cause of the air compressor failur...

詳細を見る -

極低温冷凍機におけるクライオポンプの設置ポイント

1243クライオポンプは極低温冷凍機の構造上、必要不可欠なものです。低温冷凍庫メーカーであるLNEYA社は、クライオポンプを設置する際には、その要件に従って運転する必要があることを皆様にお伝えしています。設置の容易さ

詳細を見る -

Heat transfer oil of explosion-proof cooling and heating circulator

961Explosion proof cooling and heating circulator is a commonly used temperature control equipment in laboratories. It is used in pharmaceutical, chemical, biological and other industries to provide heat and cold sources for reactors, reactors, etc. ...

詳細を見る -

高精度半導体定温直列蒸発器の冷凍効果

876装置の異なるモデルの高精度半導体恒温シリーズは、蒸発の選択も異なっており、その後、熱交換器は、高精度半導体恒温にどのような影響を与えるか...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー