極低温プロセス冷却システムを用いた全カンナビノイドの効率的抽出方法

Although cannabis plants have been used for medicinal purposes for thousands of years, modern science has identified steroids, flavonoids and more than 100 therapeutically active compounds known as cannabinoids.

Due to the significant synergy between different cannabinoids and terpenes (aromatic oils responsible for the aroma of cannabis plants), it is more beneficial to use natural cannabis based formulations rather than any single purified or synthetic cannabinoid.

As more and more governments and their states legalize the medicinal use of cannabis, there must be a safe and effective way to extract and isolate plant cannabinoids.

Alcohol extraction is the oldest and most common method of plant extraction. It has excellent solubility in lower alcohols such as ethanol and isopropanol, and cannabinoid extraction is effective as long as the water content in the alcohol is small. Prior to the ban, ethanol cannabis tinctures are part of the traditional pharmacopoeia and can be obtained from corner pharmacists.

Although many lower alcohols are suitable for efficient cannabinoid extraction, the extraction industry preferably uses ethanol due to its availability, handling and health safety, and it does not require high pressure extraction. Most interestingly, extraction with ethanol will produce a full spectrum extract that contributes to the synergistic activity of the plant cannabinoids to exert superior pharmacological activity.

Ethanol contains polar and non-polar moieties that dissolve hydrophilic and hydrophobic molecules. The polar group of ethanol dissolves hydrophilic compounds such as chlorophyll, pigment and tannin. The non-polar groups of ethanol are used together with hydrophobic ingredients such as vegetable waxes/fats, oils, cannabinoids, terpenes, and any other substances present inside or outside the plant.

On average, cannabis plant shoots produce about 12.5% of the extract concentrate. Since the buds must be completely covered during extraction, the solvent volume to plant mass ratio must be about 20 or higher, which reduces the feasibility of the process and project because a large amount of solvent ethanol must be distilled off.

Regardless of the solvent used for extraction, the extractor and extraction process must be carefully and appropriately designed in the plant cannabinoid extraction industry to obtain maximum yield with maximum cannabinoid without any thermal degradation in the extract. This level of quality is achieved by using temperature parameters and other physical process steps in the extraction.

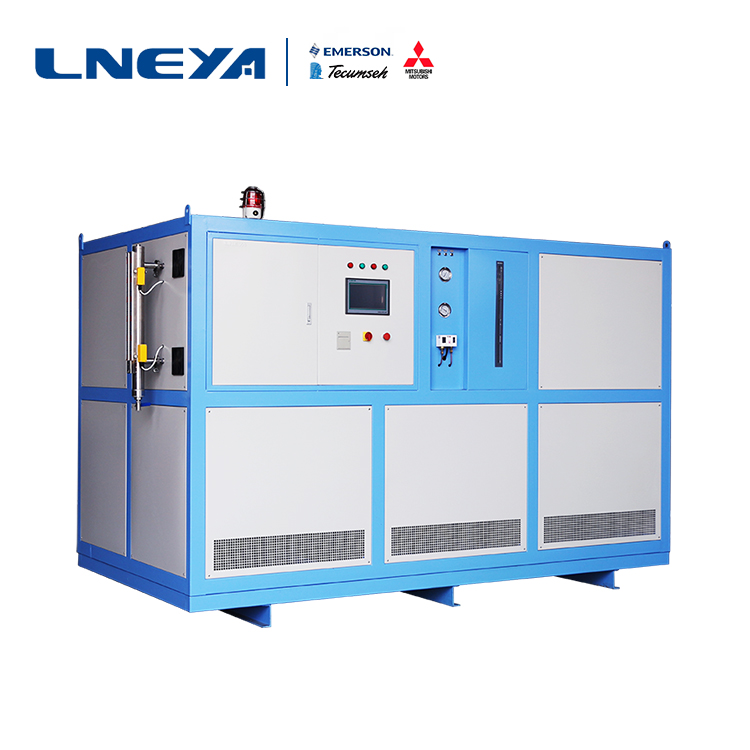

Temperature is an important step in the extraction process. Methods and equipment systems are indispensable. The Lneya cryogenic refrigeration system is essential as a cooling solution in the extraction process.

関連推奨品

-

What Should Be Noticed In Detail When Installing A Precision Chiller?

1228First, when installation, everyone needs to check whether your cold water machine works normal, whether the accessories are all right, whether there is damage, so as to avoid problems in installation. Second, when installing, the site of the preci...

詳細を見る -

半導体製造業界向けデュアル・チャンネル・チラー

969デュアル・チャンネル・チラーは、半導体製造業界の様々なプロセスで使用されています。その主な目的は、半導体製造プロセスの装置が確実に動作するように、正確な温度制御を提供することです。

詳細を見る -

What should pay attention to after purchasing the -150°C ultra-low temperature refrigerator?

1222-150 ° C ultra-low temperature refrigerator is used in the industry, so what should users pay attention to after purchasing equipment from the manufacturer? Next, Wuxi Guanya (LNEYA)-150 °C ultra-low temperature refrigerator manufacturers for ever...

詳細を見る -

チラークーラーの使用中に沈殿物が発生する原因は何ですか?

892チラーは、水の循環を利用して一定温度、一定流量、一定圧力の冷却水を供給する水冷ユニットです。LNEYA冷水システムは独自の作動原理を持ち、つまり、一定量の水を注入...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー