高温および低温冷却システムの主な故障箇所のトラブルシューティング

When the industrial high and low temperature cooling system is in use, what is the general reason if the temperature cannot drop down? How should we deal with such failures?

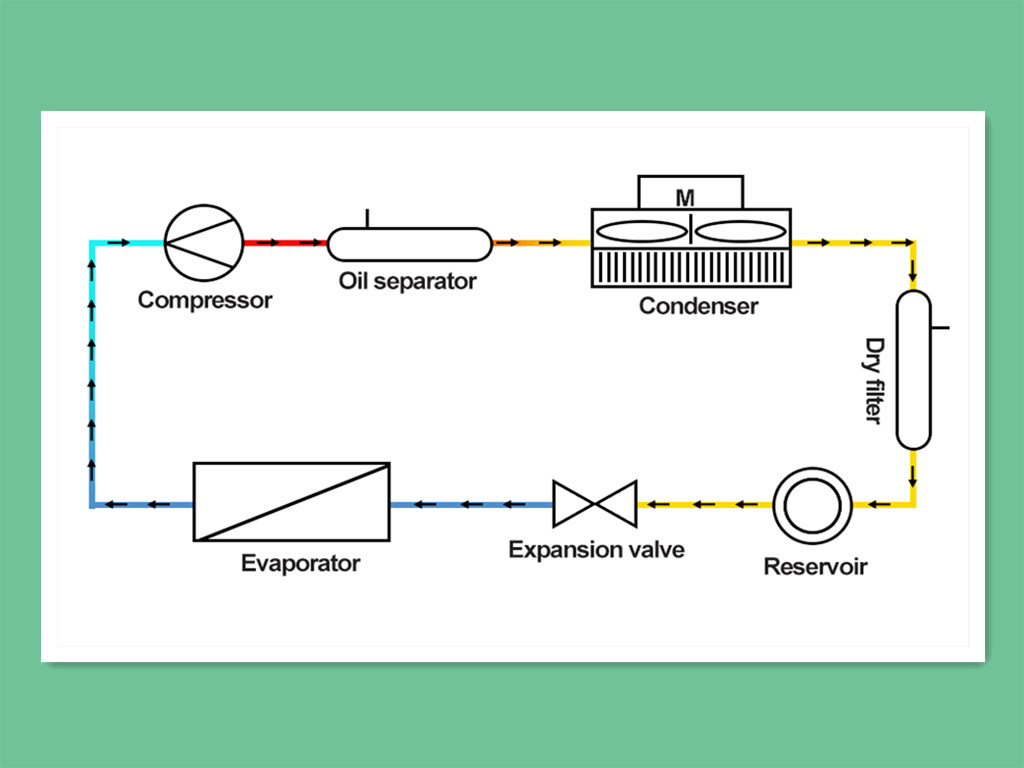

Let’s first analyze the principles and methods of industrial cooling. The circulating heat transfer medium is different. Generally, the high and low temperature cooling system industry mostly uses direct cooling, while indirect cooling is used, with plate heat exchangers or oil coolers installed inside. In other devices, the heat medium and cooling water source in the system exchange heat in the heat exchanger to reduce the temperature of the medium.

The temperature of the high and low temperature cooling system cannot be reduced. Generally, we conduct inspection and maintenance from the following aspects:

1. The cooling solenoid valve is damaged: it is necessary to check whether the solenoid valve coil can work normally, if it is damaged, it needs to be replaced; the panel does not output a cooling signal, carefully check the circuit or use the component replacement method to check.

2. Circuit failure: Check the circuit part of the system, the cooling water inlet or outlet pipeline is blocked: check whether the valve in the cooling water pipeline is fully opened, and ensure that the flow and pressure of the cooling water are sufficient, and the heating contactor is stuck, Always heating: observe the pull-in state of the contactor, and worsen damaged electrical parts.

In addition to troubleshooting the above two possible causes of failure, we also need to check whether the cooling plate is replaced or the cooling exchanger is blocked.

The advantage of using indirect cooling is that it has high temperature control accuracy and strong adaptability. It can be applied to the temperature control of high and low temperature cooling system industries. And because the heat transfer medium is cooled first, the cooling impact on the temperature control equipment is relatively small. Of course The disadvantage is that the cooling speed is relatively slow, and the price is more expensive than direct cooling.

関連推奨品

-

完全密閉式冷凍・暖房機の運転特性の説明

1402石油、化学、製薬業界では、完全密閉式の冷凍・暖房一体型機械が多くの企業で必要とされている。しかし、ユーザーが選択する際には、その運転特性を理解する必要がある。

詳細を見る -

120度の超低温冷蔵庫のオイル不足とは?

1201The compressor of the -120 degree ultra-low temperature refrigerator is a complex component that runs at high speed. In order to ensure sufficient lubrication of the moving parts of the compressor crankshaft, bearings, connecting rods, pistons, et...

詳細を見る -

ISG/TMモーターテスト冷却システム高電圧故障と処置対策

1221ISG/TMモーター試験冷却システムは、業界では空冷式と水冷式の2種類に分けられます。動作原理は、まず機械の水タンクに一定量の水を注入し、ISG/TMモーター試験を通過させます...

詳細を見る -

小型水冷式チラーのコンプレッサー点検と定期メンテナンス

1056お腹が空けば食事をしなければならないし、機械が壊れれば当然修理しなければならない。小型の水冷式冷凍機は、毎日使う中で定期的なメンテナンスなどが必要になる。今日は、そんな小型水冷チラーのメンテナンス方法をご紹介しよう。

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー