化学工業における工業用冷水機のデバッグ手順

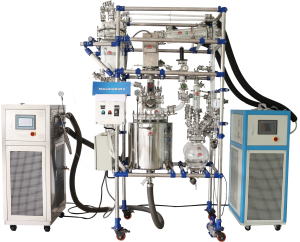

After completing the installation of industrial water chillers in chemical enterprises, certain debugging needs to be carried out in the early stage of operation. Only through careful debugging can we find out whether there are hidden troubles in the operation of the equipment.

If the enterprise can discover the hidden troubles of the industrial water chiller in the initial stage of installation, the failure rate in the later stage will be very low and the energy consumption will be less.

The effect of debugging directly affects the operating life of the equipment. If the company can discover the faults of the industrial water chiller in a short time, the operating coefficient of the chemical Industrial water chiller is very high. Due to the initial stage of the installation of industrial chemical , installers may have poor performance of industrial water chiller due to various reasons. If the industrial water chiller are directly operated, many small faults may not be discovered in time. Before operating the Industrial water chiller, it can be carefully debugged, and most of the faults can basically be judged, so as to reduce the failure rate of the Industrial water chiller.

Make a suitable debugging plan according to the use environment:

In order to ensure that the debugging effect is obvious, when the basic function is debugged, the enterprise needs to be able to formulate a commissioning plan according to the environment in which the circulating water chiller is used; it can be used for the initial commissioning of the Industrial water chiller installation and operation, which can avoid the equipment Glitches.

Debugging Notes:

In order to obtain satisfactory debugging results, the company needs to complete the overall debugging of the industrial water chiller in accordance with the requirements of the instructions. The ability to use debugging to discover potential failures in time can prevent equipment from being affected by various failures, effectively prolong the life of the unit, and greatly reduce the cost of enterprise use.

Before debugging, it is necessary to carefully check whether the circuit system and pipeline of the industrial water chiller unit are operating normally, and the equipment should be turned on under the condition of ensuring that the equipment is normal, so as to avoid equipment failure due to incorrect opening steps. At the beginning of installation, careful debugging must be carried out. The better the debugging effect, the higher the probability of discovering various potential faults. It can solve some abnormal operation and minor faults in time, which can reduce the energy consumption of the unit.

For other questions about the industrial chiller unit, you can consult our LNEYA technicians sales@lneya.com. We will reply to you as soon as possible.

関連推奨品

-

産業用冷凍機の性能を向上させる部品とは?

1068工業用冷凍機は、LNEYAの生産に欠かせない設備です。その正常な運転によって、私達はよりよい仕事の効率およびより高い製品品質を有する。工業用冷凍機の冷凍システムは、主に4つのコアコンポーネントで構成されています。

詳細を見る -

低温チラーはどのような産業に役立つか?

942Maybe some of you don't know much about low temp chiller products. The low temp chiller is a kind of professional refrigeration equipment used in industrial production. In recent years, there has been a great demand for different types of low temp...

詳細を見る -

実験室/生物工学温度制御システムの使用とメンテナンス

9461.使用する前に取扱説明書をよく読み、操作の手順と重要な指示を熟知し、取扱説明書に指定された条件に従って操作してください。2.実験室/生物工学の温...

詳細を見る -

流体伝熱温度制御システムの操作ミスを防ぐには?

990流体伝熱温度制御システムの運転中、流体伝熱温度制御システムが故障した場合、主な原因は操作ミスである。では、どうすればミスを避けることができるのか。1.1.流体熱伝達温度制御システムの操作...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー