電池の記述のための新エネルギー車電池試験装置

Lead-acid battery raw materials are easy to obtain, the price is relatively low, the high rate discharge performance is good, the temperature performance is good, can work in the environment of -40~+60 °C, suitable for float charging, long service life, no memory effect, used battery Easy to recycle, it is conducive to protecting the environment. However, the energy is low, generally 30~40Wh/kg, the service life is not as good as the Cd/Ni battery, and the manufacturing process is easy to pollute the environment. It must be equipped with three waste treatment equipment.

Compared with lead-acid batteries, nickel-metal hydride batteries have a large increase in energy density, weight energy density of 65Wh/kg, volume energy density increased by 200Wh/L, high power density, high current charge and discharge, good low-temperature discharge characteristics, and circulation. Life expectancy, environmental protection and no pollution, the technology is mature compared to lithium-ion batteries. The normal working temperature range is -15~40°C, the high temperature performance is poor, the working voltage is low, and the working voltage range is 1.0~1.4V. The price is higher than that of lead-acid battery and nickel-hydrogen battery, but the performance is worse than lithium-ion battery.

Lithium-ion battery has high specific energy, high voltage platform, good cycle performance, no memory effect, environmental protection, and no pollution. It is currently one of the most promising electric vehicle power batteries. New energy vehicle battery test equipment can also be applied to such battery devices.

The fuel cell has higher specific energy, long driving mileage, high power density, high current charging and discharging, environmental protection and no pollution. The system is complex, the technology maturity is poor, the hydrogen supply system is lagging behind, and there is a high demand for sulfur dioxide in the air. Due to serious domestic air pollution, fuel cell vehicles in China have a short life span.

について new energy vehicle battery test equipment is suitable for sodium-sulfur battery with high specific energy, high power, fast charging speed, long life, no pollution, recyclability, no self-discharge phenomenon and high energy conversion rate.

However, the working temperature is high, and its working temperature is 300~350 degrees. When the battery is working, it needs a certain heating and heat preservation, the startup is slow, and the safety is poor.

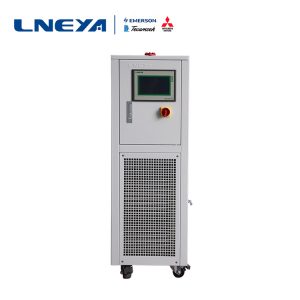

New energy vehicle battery test equipment is suitable for new energy batteries, and new energy batteries such as lithium-ion batteries, fuel cells, and sodium-sulfur batteries can be tested.

関連推奨品

-

触媒材料の製造工程における冷却装置の役割

970新材料調製の分野では、反応温度を正確に制御することで、異なる温度が材料の微細構造や巨視的特性に及ぼす影響を探り、それによって新しい材料を開発することができる。

詳細を見る -

密閉式温冷サイクル機コンプレッサーの故障修理プロセス

976LNEYA's closed-type hot and cold cycle machine adopts single-machine self-cascading refrigeration technology, and its compressor also uses the brand compressor, which is more stable in performance. Therefore, it is easy to choose a series of compr...

詳細を見る -

ゼロから86度の低温冷蔵庫を守るには?

1233低~86度低温冷蔵庫のスクロール圧縮機とピストン圧縮機は構造が異なり、逆相はできない。低~86度低温冷蔵庫の三相電源の逆相は、ピストンコンプレッサーとスクロールコンプレッサーの逆相となる。

詳細を見る -

暖房および冷房サイクル機のメンテナンス用ブート操作説明書

1156ユーザーが冷暖房サイクルマシンを選ぶとき、自分の作業に適した条件を選ばなければならないことが多く、メンテナンスと始動に関する知識にも注意が必要だ。冷暖房機の設置後...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー