密閉式温冷サイクル機コンプレッサーの故障修理プロセス

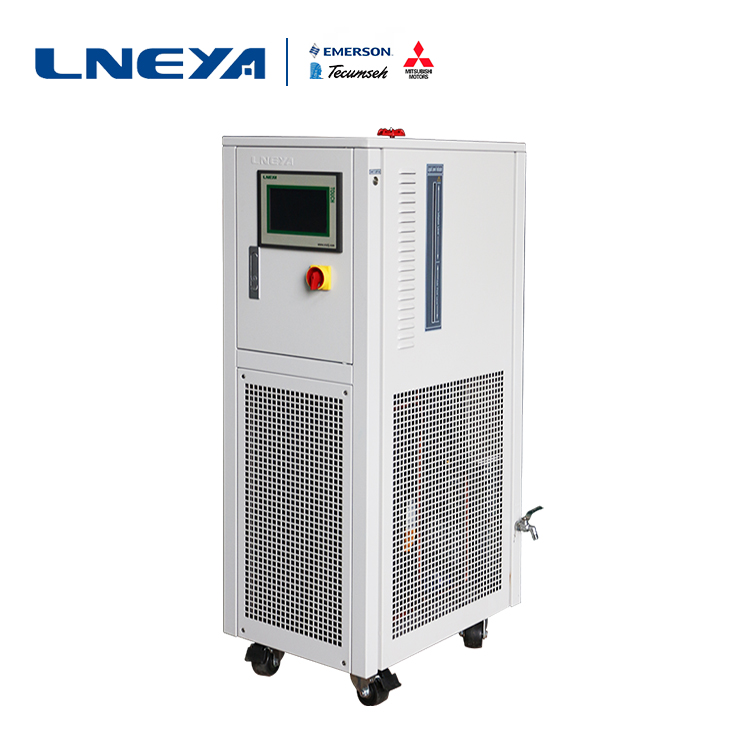

LNEYA’s closed-type hot and cold cycle machine adopts single-machine self-cascading refrigeration technology, and its compressor also uses the brand compressor, which is more stable in performance. Therefore, it is easy to choose a series of compressors with general performance. malfunction.

If the screw compressor is used in the closed type hot and cold cycle machine, the operation and maintenance process is very simple. Before the screw compressor of the closed type hot and cold cycle machine must be overhauled, if possible, the slide valve is unloaded to the “0” position. , normal shutdown, cut off the power. The compressor can be disassembled by cutting off the piping connected to the compressor and discharging the refrigerant and lubricating oil in the compressor. Be careful to develop good habits when disassembling. Parts of different parts should be placed separately and the necessary assembly marks should be made.

After removing the pipes, couplings and anchor bolts connected to the compressor of the closed type hot and cold cycle machine, the compressor is lifted to the workplace. Remove the suction filter, suction check valve, and remove the energy indicator. Remove the locating pin, remove the suction end cap in parallel, and take out the oil piston and balance piston. Note that when the positioning pin is taken, it can only be pulled out and cannot be pulled out. Be sure to take out the positioning pin first, then remove all the bolts to prevent the weight of the suction end cover from acting on the positioning pin and bend the positioning pin. Remove the shaft cover and remove the shaft seal. Be careful not to touch the moving and stationary rings, remove the positioning pin, remove the exhaust end cap, and remove the bearing gland, lock nut, washer, thrust bearing, adjusting pad, etc. To remove the locknut, use a special special tool and first open the lock tab of the lock washer. Mark them at any time and place them separately. After removing the compressor positioning pin, remove the exhaust end seat and use the special eye bolt to slowly and smoothly remove the active rotor, and do not collide with the body. At this time, the driven rotor rotates accordingly, and the driven rotor is taken out and the spool is taken out.

Wuxi Guanya (LNEYA) closed type hot and cold cycle compressor adopts Hanzhong, Bitzer, Copeland, Danfoss and other brands, and its performance is reliable. It is suitable for refrigeration, chemical and other industries, and has been highly praised by users.

関連推奨品

-

Instructions for use of various components of high and low temperature cycle machine

1159In the high and low temperature cycle machine, each accessory has its own performance advantages. When running, we need to have a clear understanding of each accessory in order to run the device better. The compressor functions to compress and dri...

詳細を見る -

グリコール・チラー・システムの冷凍原理とは?

1245Glycol Chiller System , as we can tell fromits name, it is to use Glycol as the refrigeration agent for the chiller. In the all air environment, because of thelow temperature in the outdoors, it is impossible to use a cooling tower tosupply t...

詳細を見る -

What are the maintenance of glycol chillers in daily operation?

1203In the daily operation of the glycol chiller, if the maintenance is not in place, the cooling effect will be reduced. Therefore, in order to improve the operating efficiency, we recommend that you carry out the necessary daily maintenance. Refrig...

詳細を見る -

リチウム電池試験用冷却・加熱循環装置使用上の注意事項

995専門的な実験補助器具として、リチウム電池試験用冷却加熱循環装置は、冷源と熱源の循環供給端であり、動作範囲が広い。リチウム電池試験用冷却・加熱循環装置は、冷熱源と熱源の循環供給端であり、使用範囲が広い。

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー