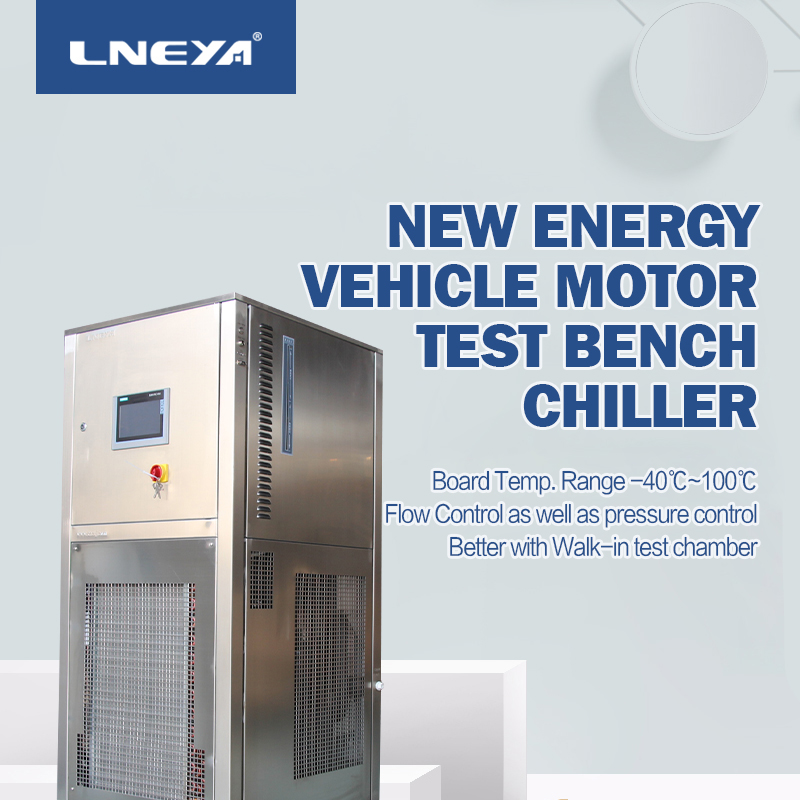

ハイブリッドカー・バッテリー試験装置冷却能力説明

Due to insufficient insulation thickness of the hybrid vehicle battery test equipment and pipeline or damage to the insulation layer, the loss of cooling capacity is increased, which affects the cooling effect. In the operation of the hybrid vehicle battery test equipment, once the outer surface of the insulation layer is found to have wet or frosted parts, it means that the thickness of the insulation material is insufficient or has been damp, and the insulation material should be added or replaced in time.

When the equipment is installed, a layer of insulation cotton is placed on the evaporator and the pipeline to prevent loss of cooling capacity. If the hybrid vehicle battery test equipment is slow in cooling, first check whether the thickness of the pipe insulation layer is not enough, or if the insulation layer is damaged, be sure to pack the insulation cotton and ensure that the thickness is sufficient!

Check for air in the equipment cooling system. When installing the hybrid vehicle battery test equipment, whether it is inside the unit, water pump, or pipeline, there can be no air, even if there is only a little air, the cold hybrid vehicle battery test equipment can not operate normally. In addition, there is a film inside the pump, and you must remember to tear it off before installation. Otherwise, the circulating water has no way to circulate or the circulation is very slow, which directly affects the operation of the hybrid vehicle battery test equipment.

Check the moving parts of the refrigeration compressor of the hybrid vehicle battery test equipment for wear, or increase the clearance, resulting in a decrease in the volume of gas. The compressor is the heart of the cooling water machine. If there is a problem with the compressor, the hybrid vehicle battery test equipment will not work. Therefore, the periodic inspection and maintenance of the compressor cannot be ignored.

The poor efficiency of equipment refrigeration compressors is also one of the reasons. In the long-term operation of the hybrid vehicle battery test equipment, the wear of the moving parts, the increase of the matching clearance or the tight sealing will reduce the actual air volume of the compressor and reduce the cooling capacity. Check the refrigeration compressor. If the repair is not good, it should be replaced in time. Air in the system can also cause this to happen. At this time, the exhaust pressure and temperature increase, the power consumption increases, and the cooling capacity decreases.

The cooling of the hybrid vehicle battery test equipment is related to the data of the hybrid vehicle battery test process, so the cooling capacity needs to be better according to the requirements.

関連推奨品

-

ワークピースの冷凍に使用される工業用冷蔵庫はどのようなモデルですか?

995ワーク・フリーザーとは-工業用冷間収縮組立技術-延命、金属冷間処理とは、金属または合金のワークをある種の媒体に入れ、適切な温度まで加熱し、この温度で一定時間保持することである。

詳細を見る -

LNEYAがAchema 2018に出展します

851The LNEYA Group will participate in the ACHEMA -World Forum and Leading Show for the Process Industries,Frankfurt am Main, Germany.You will find us from 11st to 15th June 2018.Welcome to our booth(the detailed info is coming.),

詳細を見る -

New energy testing method and application case of temperature simulation thermostat

939LNEYA new energy vehicle battery high and low temperature cycle test is one of the most widely used equipment in modern vehicle battery testing. Lithium battery is one of the more common batteries. What should be paid attention to when using it? ...

詳細を見る -

極低温冷凍システムの紹介と利点

1190The medium-sized single-fluid cryogenic refrigerator produced by our company has a cooling temperature range from -150℃ to -5℃, fast cooling speed, safe and reliable, used for rapid liquid cooling, applied to high-tech such as biochemical, freeze-...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー