一般的な高温および低温の統合された機械弁の修理の詳細な説明

The conventional high and low temperature integrated machine valve replaces the packing, and the main function of the packing is to prevent the working medium from leaking along the axial direction of the valve stem. In case of minor leakage, the packing gland can be tightened. If the leak cannot be eliminated, the packing should be replaced. When replacing, the valve stem must be screwed out to the end. Use the filler needle to pull out the old packing, then screw the prepared new packing in turn, and then tighten the gland.

In conventional high and low temperature integrated machine engineering, the valve core of a large diameter valve is sealed by a layer of babbitt or fluoroplastic. The back of the spool also has a layer of babbitt so that when the stem is rotated out of position, the working fluid can be sealed without leaking outward along the stem. After the valve is disassembled, first straighten the stem to deburr, then replace the valve’s babbitt alloy. At the same time, the valve seat should also be ground to make the valve core and the valve seat tight. For small cast steel or brass valve spools, the seal of this valve is obtained by a line of metal contact, hence the line seal. Because it is a wire seal, the valve seat and the valve core should be carefully ground to obtain a satisfactory sealing effect. After the valve is overhauled, the air tightness test shall be carried out in accordance with the relevant requirements.

The repair of the safety valve in the explosion-proof high-temperature integrated machine refrigeration system is also roughly the same as above, but since the babbitt alloy is soft, it is often difficult to return to the original position after the safety valve is operated once due to overpressure, so when the pressure is reduced to the closing pressure At the time, it is still not tight. In order to overcome this drawback, some products have changed the Babbitt alloy to a nickel-chromium-titanium (harder) alloy, or replaced with polytetrafluoroethylene.

The timely maintenance of conventional high and low temperature integrated machine valves can better help the operation of conventional high and low temperature integrated machines, so it is recommended to solve them in time.

関連推奨品

-

-80 °C 冷蔵庫メーカー動作機器ポイント

950ユーザーが-80 °C冷蔵庫を選択するとき、それは間違いなく信頼できる品質を持っている必要があります。無錫莞亜(LNEYA)-80℃冷蔵庫は、インプルーブによる機器の故障を避けるために、運転中にその操作の細部に注意を払う必要があります。

詳細を見る -

冷凍チラーのブランド企業、観亜冷凍が新たな発展をリード

968観亜冷凍技術有限公司(以下「観亜冷凍」という。(LNEYA "は英語で "Guanya Refrigeration "と呼ばれ、冷凍機器、クライオ冷凍機、超低温冷凍庫、冷蔵、加熱温調に特化したブランドです。

詳細を見る -

産業用冷凍機を選ぶ際の注意点は?

817工業用冷凍機は、冷凍機、凝縮器、蒸発器、膨張弁、制御システム、スイッチボックスなどを共通のベースまたはフレームに組み込んだ冷凍装置である。ユニットの熱除去方法によって、次のように分けられる。

詳細を見る -

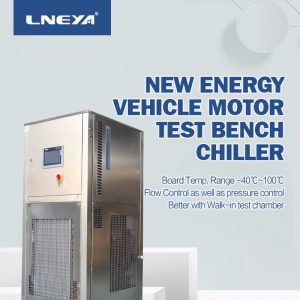

自動車用バッテリー冷却用水サイクル熱交換器には何が必要ですか?

952カーバッテリー冷却水循環装置は、常に最も人気のある設備の一つです。熱交換器の配管設計も必要です。どのような点を考慮すべきでしょうか?熱交換器には多くの種類があります。

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー