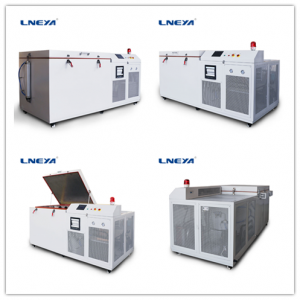

小型温調システム機器溶接メンテナンス注意事項

小型サーモスタット制御システム機器は、修理時に比較のポイントに注意を払う、LNEYA専門メーカーは、溶接部もメンテナンスの重要なポイントの一つであることを思い出し、その後、どのような側面に注意を払う必要があります...

When the small-scale thermostat control system equipment is welded, protective measures should be taken for the chassis and various components to prevent the flame from being burned by the torch. When welding, pay attention to the adjustment of the torch flame. When the flame is adjusted to the neutral flame, it can be welded. The speed should be as fast as possible to avoid damage to the compressor, the refrigeration valve body and the copper pipe.

If the copper tube is black after soldering, it should be adjusted to increase the flux flow until the copper tube is purple after soldering. When replacing the plate heat exchanger, the welding point should be soaked in water below the welding point, and the plate should be welded with a silver electrode containing 50% silver. It is forbidden to directly weld the plate heat exchanger without taking insulation measures, otherwise the temperature will be too high. After damage, after welding, it must be insulated with insulation board to prevent surface condensation. When installing, the inlet end is at the bottom and the outlet end is at the top.

The compressor of the small constant temperature control system equipment must not be placed horizontally or inverted during the handling of the compressor, otherwise the lubrication performance of the sliding part will be reduced and the compressor will be damaged when it starts. The inclination with respect to the horizontal state shall not exceed 5 degrees, and shall be welded into the system as soon as possible after the rubber stopper is removed, and the time is controlled within 10 minutes. When replacing the capillary, the length of the capillary cannot be increased or decreased arbitrarily, and when the length of the capillary is increased, an unfavorable situation will occur. When the copper tube and the capillary tube are connected, the capillary insertion depth is controlled to be about 10 mm, and the assembly gap of the copper tube brazing is 0.05 to 0.15 mm on one side.

The welded part is very important, and at the same time, it is necessary to pay attention to the strengthening of the process part. The welded part should be found by professional technicians for welding.

関連推奨品

-

-

Failures of Heating Cooling Circulators

977The heating cooling circulator can be used in many chemical pharmaceuticals and laboratories. Then, how to solve the failures of the heating cooling circulator?Failure of circulating pumpThe failure of the circulating pump is generally the heat ov...

詳細を見る -

大型冷凍機の消費電力の理由は?

951During the operation of large-size refrigeration units, the cooling capacity and working conditions are the main issues of power consumption, but in order to avoid some unnecessary power consumption, we need to understand clearly. When the scale o...

詳細を見る -

What aspects should be paid attention to when using laboratory cryogenic refrigeration circulators?

1009The compact circulating cooler is an economic model for routine laboratory applications. The instrument is cooled in the temperature range of -10 or 0°C to +40°C, and the temperature control accuracy can reach ±0.5°C. It is a good way to replace e...

詳細を見る

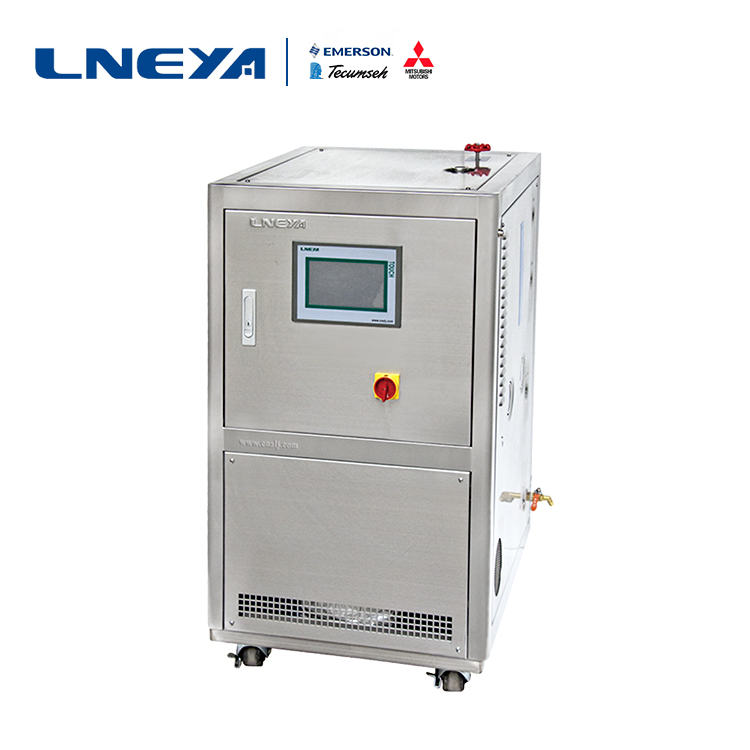

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー