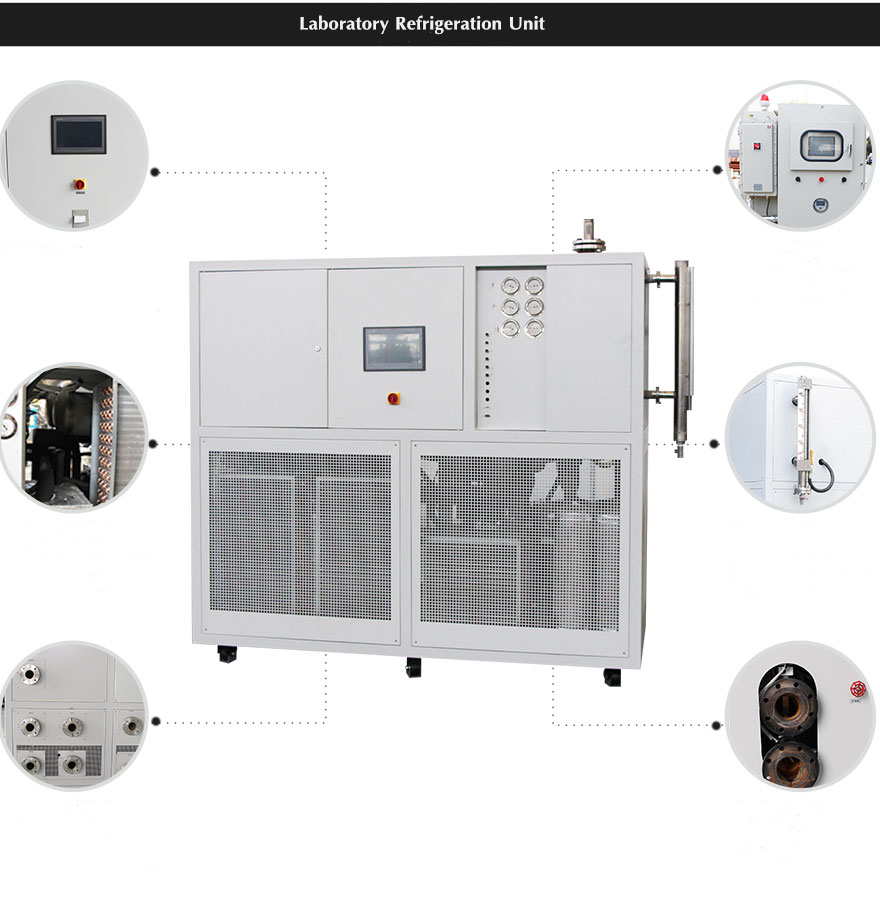

理化学機器用特殊冷凍装置の定期メンテナンスポイント

Industrial refrigeration units dedicated to laboratory instruments are used more in the pharmaceutical and chemical industries, and care must be taken when using them.

The daily maintenance of the industrial refrigeration unit dedicated to experimental instruments is mainly reflected in the following aspects:

1. Condenser

The high-temperature and high-pressure Freon of the refrigeration system of the industrial refrigeration unit dedicated to the experimental instrument comes out of the compressor and enters the condenser, releasing a large amount of heat to the cooling medium and being liquefied by the cooling.

If the industrial refrigeration unit dedicated for laboratory instruments has been used for more than half a year, or the high and low pressure engines frequently fail, or the cooling capacity is reduced, please arrange a technician to clean the condenser. The fin condenser is generally cleaned with a high-pressure water gun. Be careful not to clean it sideways, which can easily cause the fin to fall over. Shell-and-tube condensers are generally immersed and circulated with descaling chemicals, and then the end cover is opened, and the pipes are cleaned one by one with a gun gun. Cleaning the condenser can significantly improve the refrigeration efficiency of the industrial refrigeration unit dedicated to laboratory instruments.

2. Compressor

Every time the compressor operating time of the industrial refrigeration unit dedicated to the experimental instrument exceeds one thousand hours, all details of the compression equipment should be checked. For example: whether the lubricating oil is normal; whether the running current of the compressor is normal; whether there is any abnormality when the compressor is running. Of course, the current refrigeration technology is quite mature, there are many sensors and protectors. When the unit alarms the fault, it should be repaired according to the fault location. When the compressor makes abnormal noise when it is running, it should be shut down for maintenance, mostly due to insufficient lubricant.

3. Refrigerant

The industrial refrigeration unit dedicated to experimental instruments is an indispensable equipment for industrial production now, and each unit is inseparable from the participation of refrigerant, so the lack of refrigerant will affect the normal operation of the machine and will appear The cooling capacity of the industrial refrigeration unit dedicated to the experimental instrument is insufficient, or the cooling temperature is very slow.

Routine maintenance cannot be ignored. Effective maintenance can keep the industrial refrigeration unit dedicated to laboratory instruments in an effective state of operation.

関連推奨品

-

塩水噴霧環境チャンバーの一般的な不具合

1090塩水噴霧環境室のよくある故障に遭遇した場合、どのように解決すればいいのでしょうか?無錫冠雅冷凍技術有限公司は、関連する故障のヒントを以下のように持ってきた。塩水噴霧環境チャンバーが噴霧できない故障の原因...

詳細を見る -

新エネルギー自動車用パワーバッテリー試験システムにおける共通故障の分析

961新エネルギー車パワーバッテリーパックが漏れた場合、一般的な故障の顕在化モード:メーターOKランプが点灯しない、メーターは、電源システム、高電圧システムの漏れの障害をチェックするように促し、バッテリーパックとバッテリーを切断する。

詳細を見る -

半導体拡散炉構成温度制御装置

1058半導体産業において、拡散炉は半導体材料の表面にドーピング層を製造するために使用される装置である。高温加熱と制御された拡散雰囲気によってドーピングプロセスを実現する。

詳細を見る -

Guanya Refrigeration: a Brand of the Yltra-low Temperature Refrigerator Industry Assures You of…

1039Guanya Refrigeration Technology Co., Ltd. (hereinafter referred to as the "Guanya Refrigeration") brand "LNEYA" in English, specialized in refrigeration equipment, cold water machine, ultra-low temperature freezer, refrigeration, and heating tempe...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー