高温・低温液体循環式冷凍機の氷詰まりに対応する小型クーラー

高温および低温の液体循環式冷凍機の運転において、氷詰まりは比較的よく見られる故障です。関連メーカーの経験に基づき、氷詰まりに対処するためのヒントを特別にまとめました。配管内の...

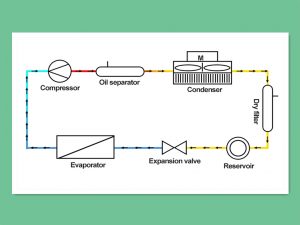

In the pipeline of the high and low temperature liquid circulating chiller, if ice blockage occurs, it is recommended to replace the damaged pipe section and repair the missing spot welding first, and redo and tighten the loose threaded joint. In order to ensure that there is no leakage in the high-pressure test of the high and low temperature liquid circulating water chiller pipeline. The high and low temperature liquid cycle chiller refrigeration cycle system pipeline is divided into high pressure section and low pressure section, flushed with four-recording carbon, and purged with nitrogen to seal for later use.

At the same time, the high and low temperature liquid circulating chiller compressor unit must be strictly processed in accordance with the steps, replacing the new filter of the high and low temperature liquid circulating water chiller, and then blown and sealed for use. The high and low temperature liquid circulating chiller refrigeration cycle system pipeline is unsealed and the compressor unit is quickly assembled After that, perform quantitative charging of the refrigerant, and wait for five minutes (waiting for the static equilibrium of the pressure in the high-pressure zone and low-pressure zone in the refrigeration cycle system pipeline) to power on and test the machine.

When the user usually faces the operation of high and low temperature liquid circulating chillers, they need to pay attention to moisture prevention and seal or seal the parts of the high and low temperature liquid circulating water coolers that are not being repaired. Maintenance is carried out in rainy weather.

However, there is always a case in case. For high and low temperature liquid circulating chillers with slight ice blockage after maintenance, the refrigerant can be recovered, replaced with new filters, or connected in series with a large cubic freezer filter at the high-pressure exhaust end, or even Refill the refrigerant quantitatively.

There are one or two ways to face the phenomenon of ice blockage in high and low temperature liquid circulating chillers. If the user does not know how to solve it, do not solve it blindly by himself. It is recommended to find a professional maintenance person to solve it.

関連推奨品

-

蒸留装置を支える超低温チラーの故障解析

1331合わせ蒸留装置に使用されているフリーザーが故障したら、実験全体の運転に影響を与えないよう、タイムリーかつ効果的な方法で解決する必要がある。製薬、化学、その他の産業では、低温...

詳細を見る -

Why is there air in the reactor temperature control system?

952The impurity gas in the reactor temperature control system is to increase the condensing pressure of the refrigeration system, thereby increasing the condensing temperature, increasing the exhaust temperature of the compressor, increasing the powe...

詳細を見る -

バイオ医薬品研究室用オイルクーラーの安定した性能を維持するには?

8991.バイオ医薬品研究所のオイルクーラーの様々な故障を防ぐために適切な作業環境は、機器のためのより良い動作環境を提供する必要があります。環境を清潔に保ち、整理整頓し、様々な...

詳細を見る -

高温および低温冷却システムの主な故障箇所のトラブルシューティング

1227工業用高温・低温冷却システムを使用しているとき、温度が下がらない一般的な理由は何でしょうか?そのような故障にどのように対処すればよいのでしょうか?まず、工業用冷却の原理と方法を分析してみよう。その...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー