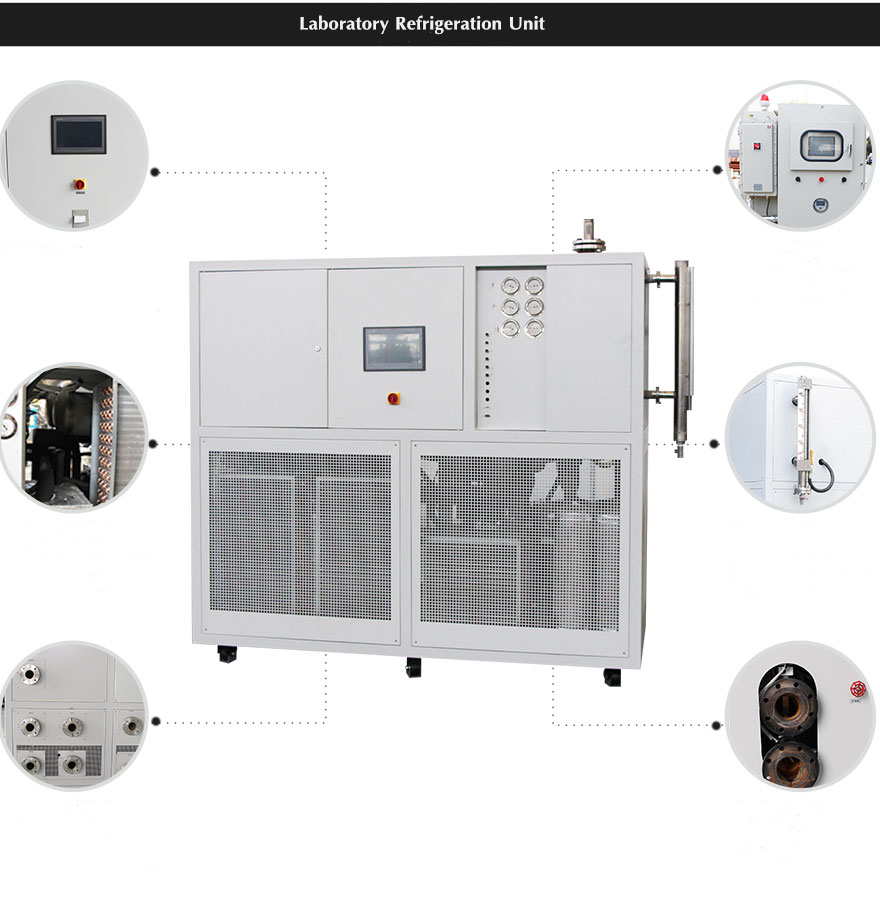

理化学機器用特殊冷凍装置の定期メンテナンスポイント

Industrial refrigeration units dedicated to laboratory instruments are used more in the pharmaceutical and chemical industries, and care must be taken when using them.

The daily maintenance of the industrial refrigeration unit dedicated to experimental instruments is mainly reflected in the following aspects:

1. Condenser

The high-temperature and high-pressure Freon of the refrigeration system of the industrial refrigeration unit dedicated to the experimental instrument comes out of the compressor and enters the condenser, releasing a large amount of heat to the cooling medium and being liquefied by the cooling.

If the industrial refrigeration unit dedicated for laboratory instruments has been used for more than half a year, or the high and low pressure engines frequently fail, or the cooling capacity is reduced, please arrange a technician to clean the condenser. The fin condenser is generally cleaned with a high-pressure water gun. Be careful not to clean it sideways, which can easily cause the fin to fall over. Shell-and-tube condensers are generally immersed and circulated with descaling chemicals, and then the end cover is opened, and the pipes are cleaned one by one with a gun gun. Cleaning the condenser can significantly improve the refrigeration efficiency of the industrial refrigeration unit dedicated to laboratory instruments.

2. Compressor

Every time the compressor operating time of the industrial refrigeration unit dedicated to the experimental instrument exceeds one thousand hours, all details of the compression equipment should be checked. For example: whether the lubricating oil is normal; whether the running current of the compressor is normal; whether there is any abnormality when the compressor is running. Of course, the current refrigeration technology is quite mature, there are many sensors and protectors. When the unit alarms the fault, it should be repaired according to the fault location. When the compressor makes abnormal noise when it is running, it should be shut down for maintenance, mostly due to insufficient lubricant.

3. Refrigerant

The industrial refrigeration unit dedicated to experimental instruments is an indispensable equipment for industrial production now, and each unit is inseparable from the participation of refrigerant, so the lack of refrigerant will affect the normal operation of the machine and will appear The cooling capacity of the industrial refrigeration unit dedicated to the experimental instrument is insufficient, or the cooling temperature is very slow.

Routine maintenance cannot be ignored. Effective maintenance can keep the industrial refrigeration unit dedicated to laboratory instruments in an effective state of operation.

関連推奨品

-

産業用冷凍機の基本構造マニュアル

1223工業用冷凍機は、コンプレッサー、凝縮器、蒸発器、膨張弁、およびその他の付属品で構成されています。1.圧縮機:工業用冷凍機システムにおいて、コンプレッサーは冷凍を確保するための動力である。コンプレッサーを使用することで、冷凍...

詳細を見る -

新エネルギー自動車駆動モーター試験システムにおける凍結油の影響

1198新エネルギー車駆動モーター試験システムにおける冷凍機油の危険性は、凝縮温度と凝縮圧力を上昇させ、凝縮器の熱伝達を悪化させる。冷凍機油の油膜は、冷凍機油に混入する油によって生成されるため、冷凍機油の油膜を除去することはできません。

詳細を見る -

化学反応におけるジャケット付きリアクター冷却・加熱システムの応用

1053化学工業において、ジャケット式反応器冷却・加熱装置は様々な化学反応に広く使用されている。様々な化学反応におけるジャケット式反応器冷却・加熱装置の応用:重合は化学反応における重要な...

詳細を見る -

具体的な運転分析 産業用冷凍庫を使用する際の除湿方法

1219工業用冷凍庫を使用する過程で、冷凍システム内に湿気が発生することがあります。そのため、工業用冷凍庫の除湿は非常に重要である。除湿を行う場合、工業用冷凍庫を購入されたユーザーは、除湿を行う前に、次のことを行う必要があります。

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー