What are the main equipment needed for industrial chillers?

Main equipment of industrial chiller: compressor, condenser, expansion valve, evaporator, chilled water pump, cooling water pump cooling tower (water cooling) Selection: know the required inlet and outlet water temperature, the required cooling capacity, select the corresponding compressor, and then According to the compressor, there are condensers and evaporators.

The chillers and industrial chillers produced by the chiller manufacturers are a kind of refrigeration device that provides chilled water, which can provide chilled water or chemical solutions at -30℃~20℃ according to the needs of users. It is especially suitable for cooling in electroplating, chemical, plastic and other production lines, as well as places where enterprises and institutions need centralized air conditioning or production processes require chilled water.

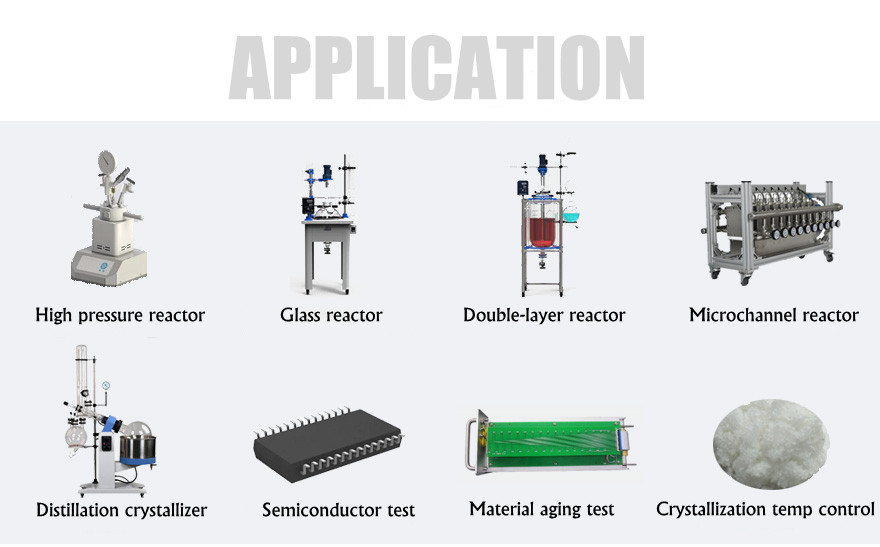

Supporting use of industrial chillers:

1. The chiller manufacturer can use the supporting vacuum equipment. This type of chiller also meets the needs of high-quality vacuum equipment, such as molecular pumps, small vacuum coating machines, etc.;

2. The water chiller can be used with supporting experimental condensing equipment; such as rotary evaporator, distiller, condenser tube, which has the characteristics of controllable temperature, stable temperature, and high condensation efficiency, which can effectively increase the recovery rate; at the same time, its fluid purification function, It can avoid the blockage of the circulation pipeline and the growth of microorganisms;

3. The chiller is used in supporting semiconductor laser equipment; due to its special structure, semiconductor laser equipment has higher water quality requirements; compared with other chillers, chillers and industrial chillers produced by other chiller manufacturers, it has a wide range of applications; except In addition to the refrigeration industry, chillers and industrial chillers are also widely used in other industries such as HVAC, electroplating, metallurgy and smelting, electronics, plastics, and chemical industries. You can see chillers and industrial chillers widely serve. Because of its cross-industry use, the space used by chillers and industrial chillers is relatively large.

要約する:

The above is an introduction to the use of supporting equipment for industrial chillers, and you can select the appropriate industrial chiller according to the different working conditions of customers. Our lneya has been intensively working in the industry for 15 years and has helped relevant customers in different industries at home and abroad to customize countless temperature solutions. You can contact us by email sales@lneya.com.

関連推奨品

-

Introduction to heating cooling temperature control system of fermentation tank

1176In the pharmaceutical and biochemical industry, the fermentation tank needs to be equipped with a heating, cooling and temperature control system to control the temperature in the system. The LNEYA refrigeration, heating, cooling and temperature...

詳細を見る -

低温チラーサーキュレーター用スクリューコンプレッサー冷凍機解説

1203Because of the different compressors, the performance of the low temperature chiller circulators is also different. Screw compressors are different from piston compressors, and the structure is more precise. Therefore, if users need to choose the ...

詳細を見る -

ルネア冷凍のサーモスタットバスSC

1435Lneya冷凍会社の恒温槽は、広く化学試薬、医薬品、生物学的製品の乾燥、蒸留、濃縮、浸漬に使用され、恒温槽加熱や他の温度にも使用することができます...

詳細を見る -

Summary – the cause of the failure of the 85 ° C ultra-low temperature refrigerator

934-85 ° C ultra-low temperature refrigerator in industrial cold treatment, with the development of industry, the scope of use is also wider. However, in the process of use, it will inevitably lead to failure, so how much do you know about common fau...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー