Cooling system of liquid-cooled energy storage cabinet-chiller

With the development of new energy technology, the application of containerized energy storage systems in new energy, photovoltaic, and electric energy stations has increased. If the temperature of the energy storage battery pack is not well controlled, the temperature of the battery will be unstable, leading to an increased risk of short circuit and damage to surrounding components.

The containerized energy storage system is mainly composed of a containerized machine room, a battery management system, and a battery pack temperature control system. Therefore, the cooling system of the special containerized energy storage system is becoming more and more high-performance and highly stable. The temperature control system includes chillers, chiller pipes, air conditioners, and air ducts. Provide suitable and stable ambient temperature for the overall container energy storage system.

During the work of the containerized energy storage system, the lithium battery system, battery management system, energy storage monitoring and other systems will generate a lot of heat due to current changes. In order to ensure the efficient operation of the energy storage system at all times, some systems will be equipped with dedicated energy storage system cooling units , The cooling method is divided into two types: air-cooled and water-cooled.

LNEYA’s energy storage integrated cabinet cooling system follows a compact design and can be an external cooling system for the battery pack energy storage integrated cabinet. Efficient nanny-style thermal management system is suitable for applications where the battery inside the energy storage container generates a lot of heat and is sensitive to ambient temperature. Integrate upper computer communication, alarm and other functions, without complicated debugging.

Liquid cooling is integrated into each battery cabinet using glycol antifreeze. The system is fully enclosed design, supports dual system cooling circuits, mutual backup to avoid battery shutdown and safety failure; intelligent, multi-language color touch screen, provides clear and comprehensive important data information, and can display flow pressure data in real time; liquid cooling system IP50 The above protection can meet the anti-corrosion requirements, and can be used below 3000 meters above sea level. The temperature setting range is -45°C~55°C, and the liquid temperature can be precisely controlled within ±0.5°C.

関連推奨品

-

液冷チラー(業務用蓄電池)

2353バッテリーエネルギー貯蔵システムは、多くのバッテリーセルで満たされており、大量の極端な熱負荷を発生させます。これは、冷却システムが温度を正確に制御し、効率的に熱を放散する必要があることを意味します。

詳細を見る -

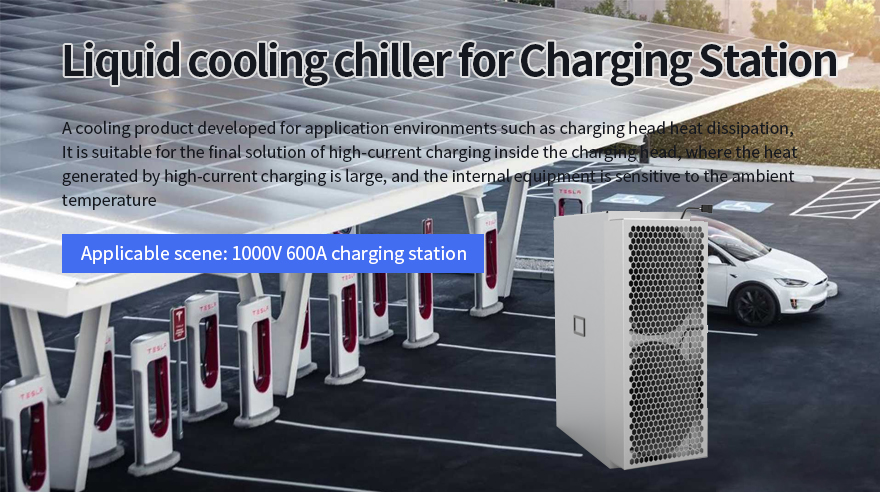

液冷チラー(チャージングパイル)

2280Model CHDYL-4 -45℃~55℃ Cooling Power 4KW Temp control accuracy ±1℃ Real-time temperature record Refrigerant Brine circulation system fully enclosed design Flow 1.8~5.5L/min Pressure 0.7bar Minimum water inlet temperature 15°C ...

詳細を見る -

液体冷却チラー(エネルギー貯蔵)

3220モデル CNYL -45~55 冷却容量 45KW 温度調整の正確さ ±0.5℃実時間温度の記録 二次冷却剤 エチレン・グリコール不凍剤、冷却する循環系の十分に封じられた設計 冷媒 R41...

詳細を見る -

How to solve the problem of poor cooling performance of the heat transfer oil circulation system?

1092Some heat-conducting oil circulation systems will not be as good as before after 3 months of use. At this time, it is recommended to contact the professional after-sales department to check the user's power supply and whether the equipment is norm...

詳細を見る -

-

Description of the characteristics of the LNEYA walk-in test chamber

850Wide temperature control range can meet the user's various needs.Unique balanced temperature control method, a stable and balanced heating capacity can be used for high precision and high stable temperature control.The temperature displayed by tou...

詳細を見る -

化学工業用冷凍・加熱サーモスタットの動作原理

1002In the selection process of the special refrigeration and heating thermostat for chemical industry, the heating power and the pressure and flow rate of the heat transfer medium are also factors to be considered. Different raw materials have differ...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー