バイオ医薬品業界におけるオイルクーラーの主な利点は何ですか?

In the refrigeration system of the oil cooler in the biopharmaceutical industry, the compressor, the evaporator and the condenser are the indispensable parts of the refrigeration system. The condenser is the equipment that emits heat, which combines the heat absorbed in the evaporator with the compressor The heat converted by the work is transferred to the cooling medium to take away together, which is responsible for the important components of the refrigeration system. If the function decreases, it will directly affect the refrigeration capacity.

There are two main types of condensers used in biopharmaceutical industrial oil coolers: air-cooled condensers and water-cooled condensers. Depending on the type of condenser, the method of cleaning the scale is also different.

1. The air-cooled condenser uses air as the cooling medium. Since there is often dust in the air, some of the dust will stick to the outer surface of the condenser fins. Over time, the cooling effect of the condenser will become worse. Especially in places where the environment is relatively harsh, it should be cleaned regularly. The cleaning method is: pure dust can be cleaned with compressor air, etc. If there is a lot of dirt, a non-corrosive cleaning agent should be used to clean the heat pipe and fins to achieve the purpose of improving the heat dissipation effect.

2. For water-cooled condensers, the main problem is to remove scale. The cleaning cycle depends on the water quality. If the water quality is poor, it can be cleaned at least once a year; if the water quality is good, it can be cleaned once every 2 to 3 years.

3. It can be cleaned with special cleaning fluid for heat exchangers. The specific operation method is: remove the condenser, release the accumulated water, and then clean the liquid in the tube until the water outlet has the position where the solution flows out.

The performance of the condenser of the oil cooler in the biopharmaceutical industry will gradually decline if it is used for a long time. As a result, the condensing pressure of the system will be higher than the condensing pressure during normal operation. Regularly protect and maintain the condenser. Here is a brief introduction to the two commonly used condenser protection and maintenance.

関連推奨品

-

低温工業用冷凍庫ファンコイルの配線手順

1115低温工業用冷凍庫の電気二方弁の赤い線は220Vの熱線(L)が直接サーモスタットの火災線インターフェイスに接続され、青い線はゼロライン(N)、コイル、二方弁、サーモスタットに接続されている...

詳細を見る -

Vocs吸着装置冷凍温度制御説明書

1090With the continuous improvement of environmental protection requirements, each factory has also concentrated the processing of vocs gas generated in production. LNEYA vocs adsorption equipment can process various vocs gases. So how much do you kno...

詳細を見る -

産業用大型冷凍庫コンデンサーの環境説明

1108工業的な低温処理において、大型の工業用冷凍庫はより多く使用される機器の一つである。その中でもコンデンサーは主要部品の一つであり、その性能は非常に重要である。そのため、選ぶ際にはやはり誰もが理解しておく必要がある。

詳細を見る -

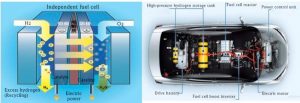

バッテリーパック極限性能試験用冷却シミュレーションシステム

1142技術の発展に伴い、純粋な電気自動車はますます一般的になりつつあるが、純粋な電気自動車は、航続距離、充電速度、バッテリー廃棄後の公害という点で、より良い解決策を得るのが難しい。そのため...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー