循環式冷凍機の機器故障アラームの対処法

What to do if there is a failure and alarm

during the use of the recirculating chiller equipment? In order to ensure

production, such problems need to be resolved quickly.

We must first understand the causes of

failures and alarms, and adopt different solutions for different causes. Common

recirculation chiller equipment failures and alarms include reverse phase

alarm, contactor jam alarm, over-temperature protection alarm, abnormal

pressure alarm, overload alarm, etc. No matter what kind of fault alarm, it can

be known according to the alarm light and alarm signal information.

1. Recirculation chiller equipment reverse

phase alarm

When a reverse phase alarm occurs in the recirculation chiller

equipment, the circulating pump cannot be started. There are two reasons for

the reverse phase alarm of the high and low temperature cold water circulation

device. One is that the phase sequence of the three-phase power line is

connected incorrectly, and the other is that the reverse protector fails. If

the phase sequence of the three-phase power cord is connected incorrectly, just

adjust the phase sequence directly. If the reverse phase protector fails, it

needs to be replaced.

2. Contactor stuck alarm

Recirculation chiller equipment contactor

stuck alarm, the over-temperature indicator will also be on, generally there

are three reasons: one is the heating AC contactor stuck, the other is the

computer board heating has been outputting, there is a problem, and the third

is the over-temperature The protection switch operates incorrectly. When the

contactor is stuck and alarms, the continuous heating of the heat transfer oil

will cause danger, so deal with it in time.

3. Alarm for lack of media

In order to protect the heating pipe and circulating pump of the

recirculating chiller equipment, the system will stop heating when there is a

shortage of media. When there is a lack of media, check whether there is a lack

of media (water or oil). If the water temperature meter shows that there is a

lack of media, you can adjust the pressure value of the pressure switch to a

lower value.

4. Overload alarm

When the recirculation chiller equipment has an overload alarm,

check whether the circulating pump is overloaded. If the pump is overloaded,

you can increase the overload current ampere.

When the recirculation chiller equipment

fails and alarms, as long as it is dealt with in time, there will be no safety

issues. LNEYA is a manufacturer of recirculating chiller equipment, equipped

with an after-sales service system. For minor problems such as fault alarms,

you can consult us sales@lneya.com for a faster and safer solution.

関連推奨品

-

反応冷却に極低温冷凍機を使用するポイント

1108極低温冷凍機はチラー、極低温冷凍サーキュレーターとも呼ばれる。低温-110度の冷凍を実現する実験装置である。この種の装置は単流体冷凍機でよく使用される。

詳細を見る -

新エネルギー自動車品質試験用KRYシリーズウォーターチラー

1031新エネルギー車パワートレイン試験台は、ハーフシャフトを介して電気駆動アセンブリの出力端に直接接続することができます。フロントエンドには、高精度のトルクセンサーとスピードセンサーが装備され、高精度なテストが可能です。

詳細を見る -

新エネルギー自動車バッテリー試験システムにおける冷媒の重要性

1259新エネルギー自動車バッテリー試験システムの冷媒の流量が極端に少ないと、冷媒はスロットルバルブの後端にある最初の膨張可能な空間から膨張し始める。スロットルバルブの後端のシースアップのほとんどは、スロットルバルブの後端にある。

詳細を見る -

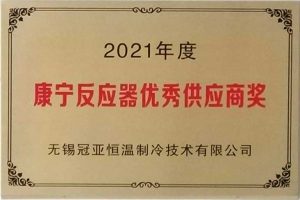

2021年度原子炉温度制御機器優秀サプライヤー」受賞

3042LNEYA was awarded the "2021 Excellent Supplier of Reactor Technology" by Corning, a Fortune 500 company in the United States. Since 2015, LNEYA has won this award for 7 consecutive years. Therefore, in the reactor manufacturing industry, we have ...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー