Which Type of Chiller Can Be Chosen for Cooling XRD?

The advantages of collecting single crystal X-ray diffraction data at low temperatures have long been recognized by the scientific community. The use of cryogenics has increased substantially in recent years with the availability of effective and reliable equipment and publications.

During the working status, X-ray tube generates a large amount of heat and needs to be cooled and protected by a cooling circulating water chiller. Without a chiller, the tube would overheat, leading to a multitude of issues including, eventually, tube failure . Usually requiring a low heat load of 5-8KW, cooling systems must provide precise temperature control for X-ray detectors to ensure maximum tube protection and longevity.

LNEYA FL series cooling system is environmentally friendly and suitable for advanced laboratory equipment. It is your best partner when looking for laboratory equipment. RG chiller and X-ray diffractometer (XRD), X-ray fluorescence spectrometer (XRFS), large field emission electron microscope, plasma etching machine, vacuum coating equipment, ion coating equipment, vacuum furnace, industrial furnace and other high-heat generating equipment Perfect match for industrial equipment. In addition, the RG series can also be used as a central chiller to meet the requirements of multiple instruments at the same time.

Featuring a closed cooler loop, it allows continuous, uninterrupted research and production at temperatures from -25 to 40°C. It is suitable for applications where reliable and rapid removal of operating heat is required in chemical production processes or where operating heat is removed from technical systems in harsh, continuously used environments. Unlike tap water cooling, this cooling circulator provides a constant temperature regardless of the time of year and pressure fluctuations. An independent cooling water system replaces the central cooling water supply system and avoids the leakage of environmentally harmful substances. Conserving water also protects the environment and significantly reduces operating costs. Applications include rotary evaporators and Soxhlet systems, analytical equipment such as electron microscopes, X-ray units, refractometers, distillation systems, X-ray control systems such as in airports and semiconductor systems, cooling trap control such as in gas drying, and Central cooling water supply completes the laboratory to replace mains water cooling.

Recommend Product

ロード...

已经是到最后一篇内容了!」。

アプリケーション

関連推奨品

-

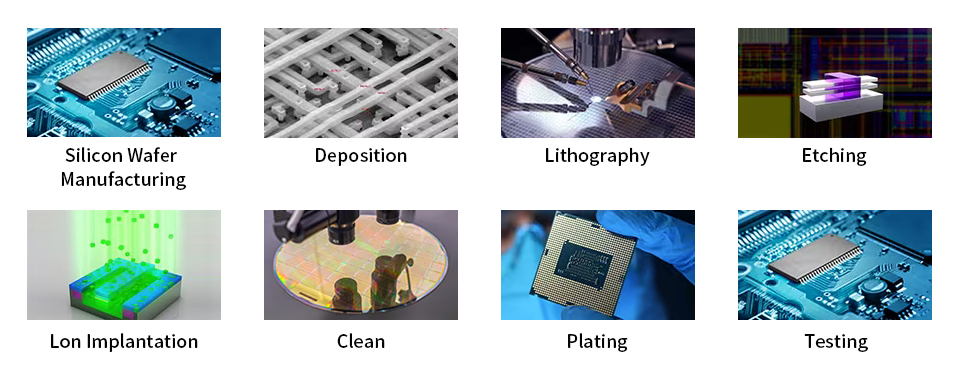

What type of chiller is needed for low-temperature etching?

935The low-temperature etching process usually requires extremely high precision temperature control and strong cooling ability to maintain stable operation of the etching equipment at extremely low temperatures, in order to achieve finer etchi...

詳細を見る -

-

Description of the action of the filter in the ultra-low temperature compressor unit

1101In order to stabilize the operation of the ultra-low temperature compressor unit, the performance of the compressor is very important, and in addition to the compressor, the filter is also important. In order to maintain normal operation, it is ne...

詳細を見る -

How to choose the model of the temperature control device of the lithography machine?

900How to choose a suitable industrial chiller, and what aspects should be paid attention to in the design of the unit?1. Choose air-cooled or water-cooled temperature control device for lithography machineThe condensation methods of industrial chil...

詳細を見る -

酸化拡散プロセスにおける温度制御と冷却装置

732酸化拡散プロセスは、半導体製造における重要なステップである。主に精密な酸化膜の形成とドーピングに使用され、温度制御には極めて厳しい条件が要求される。このプロセスでは、チラーが重要な...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー