ベアリング低温処理装置の利点

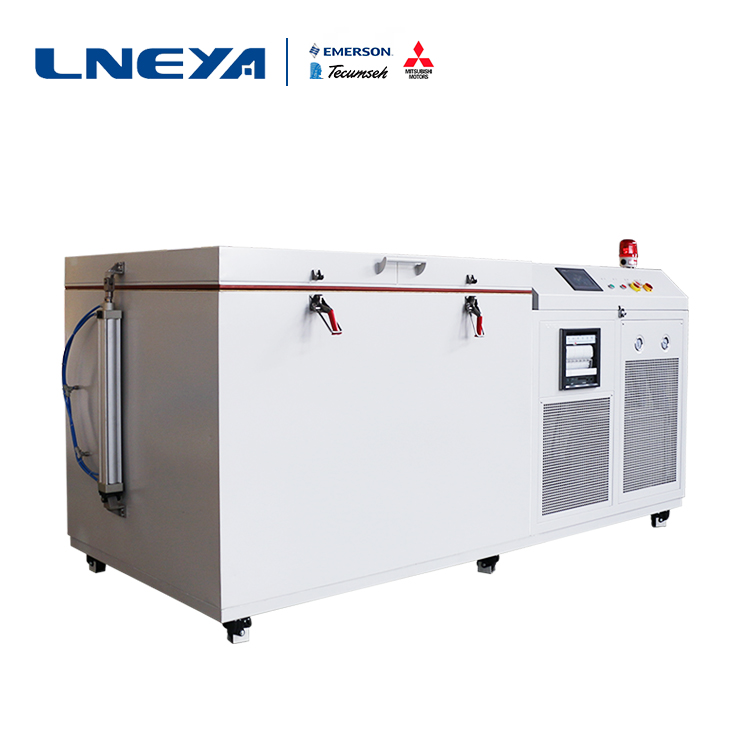

One of the names of the ultra-low temperature freezer is the bearing cryogenic treatment equipment. Wuxi Guanya LNEYA’s ultra-low temperature freezer is designed for large volume ratio; large capacity bearing capacity design; can set the temperature difference between turning on the compressor and turning off the compressor;

A variety of fault alarms (over temperature alarm, sensor alarm, high pressure alarm, compressor overheat alarm).

Cryogenic treatment is a continuation of the workpiece cooling process after quenching. The application in the mold industry is mainly reflected in the application of cryogenic technology in cold work die steel and high speed steel, bearing steel, cold work die and mold parts.

The advantages of cryogenic treatment are as follows:

1. Improve the hardness and strength of the workpiece

2. Guarantee the dimensional accuracy of the workpiece

3. Improve the wear resistance of the workpiece

4. Improve the impact toughness of the workpiece

5. Improve the stress distribution inside the workpiece and improve the fatigue strength

6. Improve the corrosion resistance of the workpiece.

Bearing cryogenic treatment equipment product structure:

The bearing cryogenic treatment equipment adopts 7-inch color touch screen (display set temperature, measurement temperature), temperature curve record, U disk data export, format is excel table, fault record, real-time monitoring temperature change inside the box, with manual and automatic double operation function . The equipment uses liquid nitrogen as the cooling medium, and the stainless steel cabinet is beautiful and durable, and is insulated by high-quality high-density polyurethane foam insulation layer. The system structure is reasonable, the manufacturing process is standardized, the components are arranged compactly, the operation is simple and powerful, and the humanized communication interface; the low temperature can reach -150 ° C, and the cooling speed is fast. The ultra-low temperature cryogenic test chamber adopts (developed by itself) Guanya company mixed refrigerant, which makes the process of constant temperature and temperature drop of the product even and stable.

Application range:

It is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides generated on the metal structure matrix. The appearance of such a carbide will bring about a significant increase in the wear resistance and friction properties of the metal, and the hardness will also increase, and will directly increase the life of the wear member. The ideal product to replace liquid nitrogen.

It is used for shrinkage of copper sleeves, bearings, etc., and is widely used in precision mechanical assembly. It is used in ultra-low temperature testing of large equipment (automobiles, large construction machinery, aircraft components, aerospace equipment components, military equipment components).

関連推奨品

-

-

原子炉の温度制御はどうなっていますか?

1170反応器冷却システムは化学工業の一般的な設備の一つである。反応プロセスの加熱と冷却のニーズを満たすために、加熱だけでなく、冷却することもできます。通常、原子炉の温度を制御する三つの方法がある。

詳細を見る -

Cooling and heating system TES for integrated circuit wafer cooling method

1103Integrated circuit products have been developed for more than 50 years and are the most advanced high-tech industries. Integrated circuit or chip / chip. The complete chip manufacturing process includes chip design, wafer manufacturing, package ma...

詳細を見る -

なぜ低温チラーサーキュレーターにフロスト現象が発生するのか?

1099多くの低温チラーサーキュレーターは使用時に霜が降りるが、低温チラーサーキュレーターには霜現象がない。では、何が問題なのか?冷凍と関係があるのでしょうか?まず、なぜ低温チラー...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー