Steaming system temperature control safety requirements

The steaming system temperature control is one of the low temperature refrigerators designed and produced by Wuxi Guanya LNEYA. The temperature range is from -5 °C to -150 °C. The secondary subcooling technology is adopted, the refrigeration is rapid, the refrigeration temperature is low, and the liquid is rapidly cooled. It is widely used in high-tech industries such as petrochemical, medical, pharmaceutical, biochemical, freeze-drying, pharmaceutical, military and so on.

Before using the steaming system to control the temperature, be sure to read the instruction manual and safety requirements, observe the safety requirements, and keep the instruction manual for the temperature control of the steaming system properly so that the operator can read it when they do not understand it.

The temperature control system needs to select the power supply according to the power supply size of LNEYA’s appearance manual. Do not share the same power supply with other electrical appliances, so as to avoid danger caused by excessive temperature control load of the steaming system. The power supply controller should be grounded as much as possible and pay more attention to whether it is firm or not. Improper grounding results in electric shock.

Pay attention to the installation diagram, power supply diagram, communication diagram, electrical diagram and other drawings for temperature control of the steaming system to install, pay attention to the separation of strong and weak electricity, transformer input, relay according to the size requirements of the description, to ensure voltage input. Please also pay attention to the installation, the location should not be in the rain, snow, waste and sun exposure, do not touch the screen controller with sharp objects, or put too much pressure on the controller to avoid damage to the touch screen.

Pay attention to the accessories that protect the temperature control system from steaming, do not pull and twist the power cord and communication line to avoid malfunction. If the equipment meets maintenance needs, please contact the manufacturer and do not repair it yourself.

If there are other problems in the safety requirements of the temperature control system, or if you cannot solve the doubts in the manual, you are welcome to consult the technical staff of the professional manufacturer for guidance.

関連推奨品

-

battery charging test conditions at different ambient temperatures

1253At present, the battery is undoubtedly the most core and critical component in electric vehicles. Therefore, both the OEM and the battery factory need to conduct a comprehensive test of the battery. The characteristics of automotive lithium-ion po...

詳細を見る -

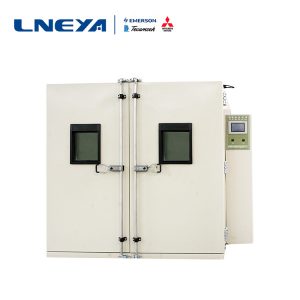

Description of the characteristics of the LNEYA walk-in test chamber

853Wide temperature control range can meet the user's various needs.Unique balanced temperature control method, a stable and balanced heating capacity can be used for high precision and high stable temperature control.The temperature displayed by tou...

詳細を見る -

How to choose a glass reactor? How to match the temperature control system?

964Glass kettle reactors are required for many laboratory equipment and are generally used with temperature control systems. In the chemical and pharmaceutical fields, the imported glass reactor is basically a necessity, and the refrigeration heatin...

詳細を見る -

Quotation of High Low Temperature Test Chamber

922When users choose and purchase high low temperature test chambers, many manufacturers like Wuxi LNEYA will explain the price factors of the high low temperature test chamber. The price of high low temperature test chamber is relatively high, which...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー