Multi-stage refrigeration system centrifugal compressor repair instructions

After the centrifugal compressor of the cascade refrigeration system is disassembled, the dimensions of each journal (cooperating with the impeller, bearing, coupling, etc.) are measured with an outer diameter micrometer to calculate the roundness and cylindricity deviation. The value should be Within the allowable range. When the tolerance is large, check if the straightness deviation of the spindle is too large. Place the spindle in the casing or place it on the top of the lathe so that the spindle is in a free state. Use a dial gauge to measure the radial runout of the spindle journal.

The centrifugal compressor of the cascade refrigeration system is divided into 4-8 equal parts, and the rotor is driven according to the direction of rotation of the rotor. The large value of the dial gauge swing is the radial circle runout value. At the same time, the straightness deviation of the main shaft is measured at the appropriate position of the main shaft with two dial gauges, and the radial runout value should be no more than 0.01mm. If the over-standard is too large, the main shaft should be replaced.

Check the surface of the journal of the centrifugal compressor of the cascade refrigeration system for scratches, grooves, scratches, grinding points, etc. If necessary, perform flaw detection. Small defects can be scraped and polished by hand; large defects It can be repaired by surfacing, electroplating, spraying, etc., and then ground and polished. When the flaw detection reveals cracks or serious defects, it is generally not repaired and replaced.

At the same time, the end face runout of the centrifugal compressor impeller of the cascade refrigeration system should be measured, and the value should be within the allowable range. If the value of the end face jump exceeds the allowable range value, when the over-standard is small, the repair is generally not performed. When the value is large, the assembly relationship between the impeller and the main shaft can be adjusted by the method of adding the gasket. The impeller should be dynamically balanced and statically balanced after the overhaul. test.

The parts and fittings of the centrifugal compressor of the cascade refrigeration system have the specified technical standards and requirements for use. In the absence of reliable basis, it is necessary to strictly abide by these standards and never lower the standard.

The cascade refrigeration system should have a fixed maintenance and repair plan, carefully learn the correct understanding and use of equipment requirements by the user, and timely cooperate with the on-site user for regular maintenance.

関連推奨品

-

真空ポンプ温度制御システムの使用における誤解

918真空ポンプの温度制御システムを使用する場合、正しい操作方法のみが装置の正常で安定した動作を保証することができます。もし間違った操作方法が多ければ、装置の正常な使用に直接影響します。

詳細を見る -

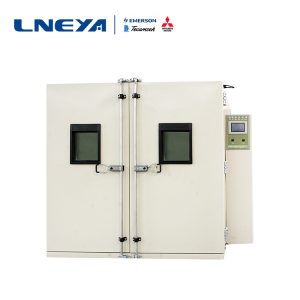

Step-by-step test box brand advantage description

1255The walk-in test box is developed and produced by LNEYA. It is specialized in pharmaceutical production technology and provides customers with various models of brands. Next, we will introduce the next step-in test box. Welcome to refer to and lea...

詳細を見る -

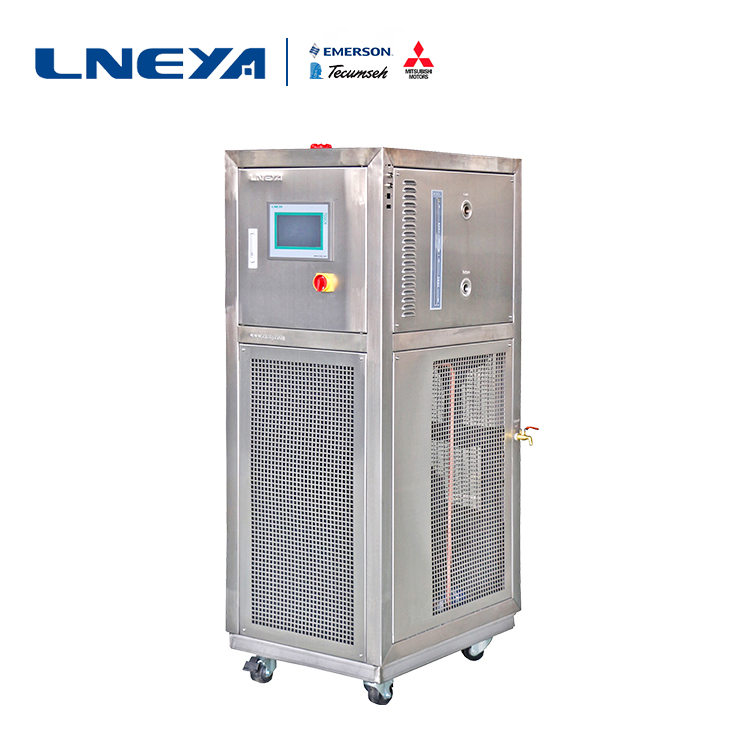

SUNDI 冷暖房システム 有機合成素材とファインケミカルの研究開発試験

1238LNEYA社の顧客は、高性能で環境に優しい有機新素材やファインケミカルの研究開発・製造に携わる研究機関である。

詳細を見る -

化学薬品・医薬品の定温制御syの動作状況を判断する方法

945現在、多くの製薬・化学業界でLNEYAの定温制御システムが採用されています。運転中の運転状態はどのように判断するのでしょうか?製薬・化学用恒温槽のシリンダー内に異音がないこと。

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー