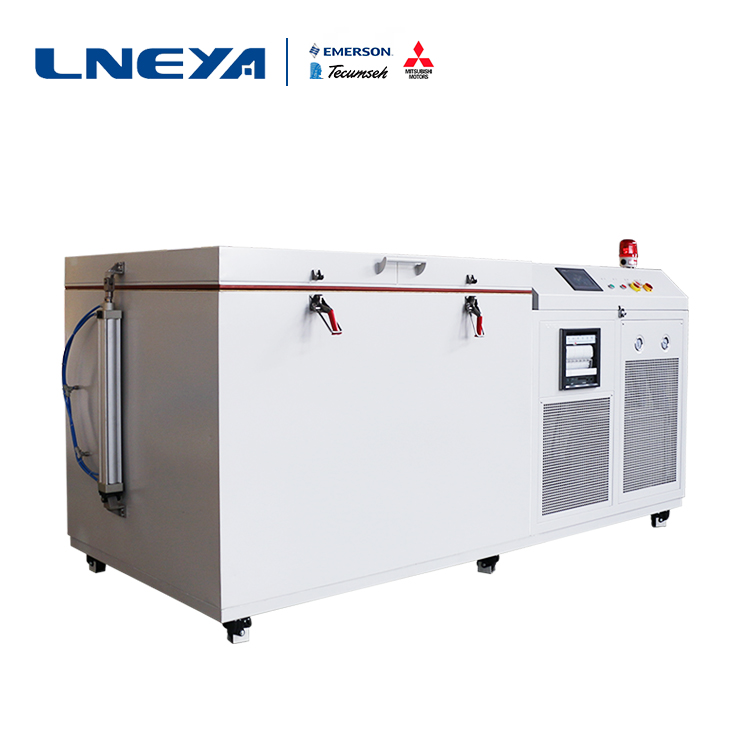

Large industrial refrigerator evaporator operation instructions

In the operation process of Wuxi Guanya LNEYA large industrial refrigerator, due to the large number of parts and complex, we need to understand the operation of the components in large industrial refrigerators. The evaporator is one of the main components, and we need to understand the operation. Better.

The large industrial refrigerator evaporator has good heat transfer effect, compact structure, small volume, convenient installation and wide application, and the structure of the evaporator is the same as that of the horizontal shell-and-tube condenser. The heat transfer coefficient of a tubular evaporator is larger in a liquid than in a gas, and is larger in a flowing state than in a stationary state. In order to control the proper flow rate in the tank, the refrigerant enters from the lower portion of the end cap, flows out from the upper portion, and flows back and forth in the evaporation tube and the end cap to become a multi-program flow. The refrigerant flows outside the tube, and the throttled refrigerant liquid enters from the bottom or side of the evaporator, and the gas after the fins is discharged from the upper portion.

When the shell-and-tube evaporator of a large industrial refrigerator is operated, a certain amount of liquid refrigerant should remain in the casing, and the liquid level is controlled by a float valve. The height of the still water surface should be approximately the diameter of the cylinder. Most of the cooling tubes are immersed in the liquid and exchange heat in a liquid-to-liquid manner.

The materials used in the evaporators in large industrial refrigerators in different industries are different. Typically, the ammonia evaporator is made of 4025 x 2.5-438 x 3 steel tubes and the Freon evaporator is made of copper or brass tubes. In order to improve the heat transfer effect, Freon evaporators mostly use finned tubes. The upper portion of the evaporator barrel is typically filled with fewer rows of cooling tubes or the air pockets are welded to the housing to separate the gas stream before exiting the evaporator. Large evaporators typically produce dedicated separation devices. When the shell and tube evaporator of a large industrial refrigerator is operating, a certain amount of liquid refrigerant should remain in the housing.

Different large industrial refrigerator manufacturers may choose different models when configuring the evaporator, so the user needs to know the configuration clearly when selecting.

関連推奨品

-

エア・コントロール・システムの清掃方法は?

1266In order to respond to the requirements of the two types of society in the country, environmental protection and conservation have become increasingly important. Therefore, in order to extend the life of the product, it is still necessary to have ...

詳細を見る -

空冷式産業用チラーの特性分析

913Industrial air-cooled chillers are generally integral machines, that is, evaporator, compressor and condenser are made together. For a slightly high-power air-cooled industrial chiller, the heat dissipation of the condenser cooling fan needs to be...

詳細を見る -

実験室用晶析温度制御冷却・加熱システム

861実験室での晶析プロセスにおいて、温度制御された冷却・加熱システムは、晶析液の温度を正確に制御するために使用される重要なコンポーネントである。

詳細を見る -

Introduction Of Low Temperature Refrigeration Equipment Series-low Temp Process Chillers

924Thermoacoustic refrigeration technology is a new refrigeration method with wide application prospects. It is one of the major advances in refrigeration and cryogenic technology in the past 30 years. Thermoacoustic engine uses thermoacoustic effect...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー