Prospects for the development of electronic test thermal systems

For the modern society, energy conservation and emission reduction is also an important task. In the development of semiconductor, chip, integrated circuit and other industries, the electronic test thermal system can effectively test its temperature range to ensure that such components can Effectively get test results to avoid energy waste and increase costs.

The electronic test thermal system has a cooling function when passing through direct current. Since the semiconductor material has considerable thermoelectric energy conversion performance characteristics, thermoelectric cooling is called an electronic test thermal system. The electronic test thermal system can improve the actual cooling performance of the electronic test thermal system by optimizing the design of the electronic test thermal system module, reducing the difference between the ideal performance coefficient of the electronic test thermal system module and the actual performance coefficient.

Since the heat dissipation of the electronic test thermal system is equal to the sum of the cooling capacity and the input power, the heat dissipation effect of the electronic test thermal system is an important factor affecting the refrigeration performance of the semiconductor. The electronic test thermal system adopts various types of enhanced heat dissipation methods to improve the cooling efficiency, and there are natural convection heat dissipation, forced convection heat dissipation, water cooling heat dissipation, phase change boiling heat transfer, etc., all of which can receive good results. Since the choice of heat dissipation method is very important in the design of the electronic test thermal system, the choice of which method should be combined with the use of the electronic test thermal system and the heat dissipation efficiency.

In recent years, research on electronic test thermal systems has received extensive attention from scholars at home and abroad. The subjects of interest are all-encompassing and involve almost all fields, such as military, scientific, aerospace, industrial, agricultural, medical, biochemical and daily necessities.

At present, domestic and foreign scholars’ research on semiconductors mainly focuses on semiconductor materials research and development, module design and manufacturing, and system optimization design. This requires the analysis of semiconductor refrigeration in principle. At the same time, the optimization of the performance characteristics of the electronic test thermal system and the heat dissipation conditions of the system are also the hotspots of the electronic test thermal system research. By studying the excellent value coefficient Z of the electronic test thermal system, the manufacturing process of the electronic test thermal system, and the design external change Thermal mode, optimized internal thermocouple structure and overall electronic test thermal system device structure. With the rapid development of science and technology, the size of product devices is getting larger and larger, some are getting smaller and smaller, some conditions are more and more complicated, and many factors need to be considered. How to solve the optimization problem of high-power semiconductor multi-stage refrigeration, the local heat dissipation problem of small-sized devices, and the multi-factor semiconductor thermoelectric energy conversion problem have become the contents of continuous research in the future.

The combination of electronic test thermal system and semiconductor industry, its use range is also more and more extensive, and its electronic test thermal system temperature control is not only mature, but also has certain development space in the future.

(注:原文の一部は関連論文からの引用です。著作権侵害の場合は、削除いたしますので、お手数ですがご連絡ください)

関連推奨品

-

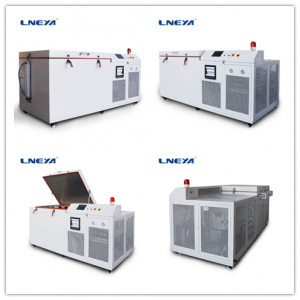

Description of LNEYA industrial ultra-low temperature freezer

1258LNEYA industrial ultra-low temperature freezer is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides on the metal structure matrix. The appearance of such a carbide will bring about a significant increase ...

詳細を見る -

Motor cooling system tests the effect of condensing temperature

1276The motor cooling system tests the condenser. Under normal conditions, the first half of the heat pipe is very hot, and its temperature has a slow and slow gradual decline in the balance of power. The heat sensitivity of the second half of the hea...

詳細を見る -

空冷式スクリュー冷凍機の3つの一般的な故障

13161.通信障害:コンピュータ・コントローラは、電気通信回線とトータル・インターフェース・ボードによって様々なモジュールを制御しているため、通信障害の主な原因は、通信回線の接触不良や断線、特にインターフェース・オキシダ...

詳細を見る -

Motor test chiller compressor causes wear

1078Motor testing chiller oil quality may be one of the main reasons affecting crankshaft wear. If the engine oil is used in the chiller refrigeration system, the engine oil that does not meet the requirements and is of poor quality may cause cranksha...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー