半導体チップ用高温・低温試験機の必要性

The rapid development of the chip industry is also obvious to everyone. LNEYA semiconductor chip high and low temperature test machine has also been continuously developed along with the development of the chip industry.

There are tens of thousands of chips running daily in large companies, and the pressure on semiconductor chip high and low temperature testers is very large. When the chip is made by the fab, it will enter the Wafer Test phase. Testing at this stage may be performed at the fab or sent to a nearby test vendor agent. The production engineer will use the automatic test instrument (ATE) to run the program given by the chip designer, and roughly divide the chip into good/bad parts. The bad ones will be directly discarded. If there are too many bad films at this stage, the basic will It is believed that the fab’s own yield is low. If the yield is below a certain value, the fab needs to lose money.

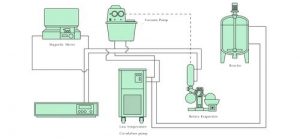

After passing the Wafer Test, the wafer will be cut. The cut chips are sorted according to the previous results. Only good chips will be sent to the package factory. The location of the package is generally near the fab because unpackaged chips cannot be transported over long distances. The type of package depends on the needs of the customer, some require a spherical BGA, and some require a pin. In short, this step is simple and has fewer faults. Since the success rate of the package is much larger than the production yield of the chip, it will not be tested after packaging. After packaging, the chip will be sent to the test factories of major companies, also known as production plants. And carry out the Final Test. There are actually more than a dozen processes in the production plant, and Final Test is just the first step. After the Final Test, you also need to sort, engrave, check the package, package and other steps. Then you can ship to the market. Final Test is the focus of the factory and requires a lot of mechanical and automation equipment. Its purpose is to rigorously classify chips.

Users can find out that the chip test results affect the quality and performance of the product by using the semiconductor chip high and low temperature tester. (This article source network, if there is any infringement, please contact delete, thank you)

関連推奨品

-

LNEYA 低温チラーセレクションの分類説明

1288無錫莞亜(LNEYA)の低温冷凍機は、企業や業種によって求めるものが違います。機種の選択も異なるので、選択の際にはそれらを理解した方が良い。低温チラー...

詳細を見る -

ロータリーエバポレーター用低温クーラント循環ポンプ

1282極低温冷却液循環ポンプの最大の最終消費市場は、化学および製薬分野である。この市場における低温冷却液循環ポンプへの需要の増加に伴い、極低温ポンプの用途は...

詳細を見る -

抽出・分離における高温・低温循環装置の使用方法とは?

879科学技術の絶え間ない発展に伴い、高温・低温サイクルの工業用温度制御機器は、多くの分野、特に抽出と分離の分野で重要な役割を果たしている。本記事では...

詳細を見る -

化学冷却および加熱システム - 動的温度制御システムメーカー

846製薬・化学業界では、冷暖房システムが広く使われている。インターネットの発展に伴い、多くの企業が熾烈な競争を繰り広げています。以下は、LNEYA化学冷暖房システムの利点を紹介します...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー