機械式冷間組立装置は、金属部品の冷間加工組立専用です。

機械式冷間組立装置は、-130℃以下の温度でワークを加工する方法である。極低温処理は、ワークピースの強度や硬度を低下させることなく、ワークピースの靭性を大幅に向上させることができる。機械的...

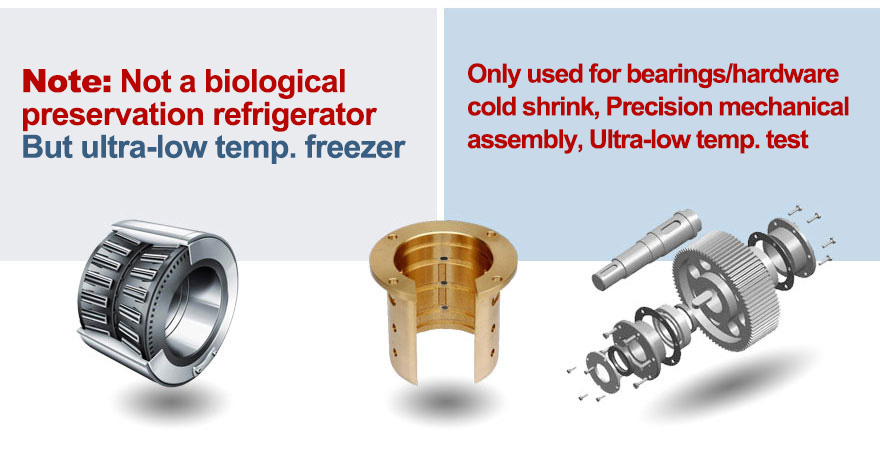

Mechanical cold assembly equipment is suitable for containing parts (such as planet carrier, torsion arm, etc.). If the parts cannot be heated or heating parts will cause parts accuracy, material organization changes, and affect their mechanical properties, the contained parts (such as pins and elastic support shafts) can Assembly of frozen interference fittings. The equipment for cold assembly of crankshaft machinery is suitable for all kinds of hot work molds, cold work molds assembly, gears and shafts assembly of various gearboxes, gearboxes, elaborate mechanical parts assembly, various motor stators, rotor assembly, automobile parts Engine parts.

When the hole piece is large or irregular in shape, and the pressed parts are small, cold fitting can be used when it is difficult to implement the method of heating the hole piece. The specific method is to cool the contained part at a low temperature to reduce its size, and then install it into the part with holes.

Mechanical cold assembly equipment can improve the fine structure of the matrix, strengthen the matrix structure, strengthen the dimensional stability, and make the hardness through the cryogenic processing of various tools, cutting tools, molds, drills, secret mechanical parts, nozzles, gears, and bearings. , Impact toughness and wear resistance are significantly improved, effectively extending the service life of the workpiece.

Mechanical cold assembly equipment can transform a large amount of residual austenite in the metal into martensite during cryogenic processing, especially supersaturated metastable martensite will reduce supersaturation from -150 ℃ to room temperature. Precipitation of dispersed ultrafine carbides can reduce martensite lattice distortion and reduce microscopic stress, while finely dispersed carbides can hinder the movement of dislocations during plastic deformation of the material, thereby strengthening the matrix structure. At the same time, due to ultrafine carbide particles After precipitation, they are evenly distributed on the martensite matrix, which weakens the grain boundary embrittlement, and the refinement of the matrix structure not only reduces the degree of segregation of impurity elements in the grain boundary, but also exerts the grain boundary strengthening effect, thereby improving the workmanship. The performance of the mold significantly improves the hardness, impact resistance and wear resistance.

Wuxi Guanya LNEYA specializes in the research, development, manufacturing and sales of cryogenic equipment in the field of low temperature, mainly producing mechanical cold assembly equipment and ultra-low temperature freezer.

関連推奨品

-

Semiconductor production process and testing process temperature control unit

958LNEYA semiconductor testing process chiller

詳細を見る -

産業用チラーユニットの冷媒交換プロセスの全解析

1002Refrigerant is an indispensable part of the refrigeration system of the industrial chiller. During the operation of the industrial refrigeration unit, the refrigerant constantly changes in the industrial refrigeration unit to achieve the cooling e...

詳細を見る -

LNEYA低温チラーの開発

946経済の国際化に伴い、無錫冠雅はチャンスをつかんだ。中国国内で急速に発展しているだけでなく、積極的に海外市場を開拓し、低温度帯の発展における重要な企業の一つとなっている。

詳細を見る -

Suitable Freezer Manufacturer

915For enterprise users, choosing a suitable freezer manufacturer is very important and must be carefully treated. Wuxi Guanya Refrigeration technology co., Ltd, as a professional freezer manufacturer, is committed to producing all kinds of low tempe...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー