The significance of temperature in IC testing

Every integrated circuit (IC) goes through two type of tests before it can be sold and used to build a product: the first is called a wafer test; the second is called final test.

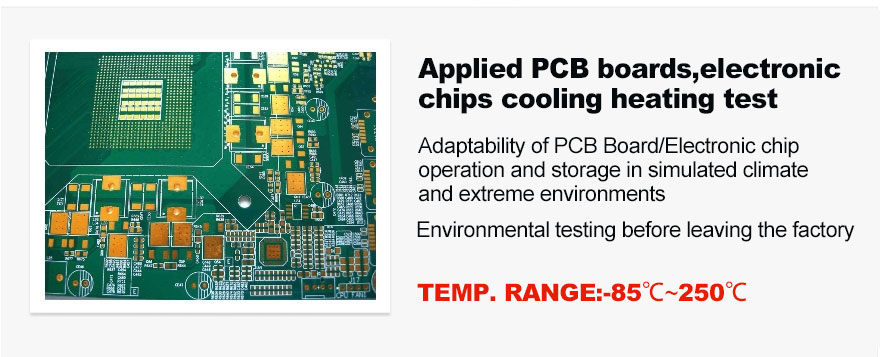

With the improvement of integrated circuit electrical test technology and requirements, some chip products have integrated temperature sensors, or through the voltage changes of some precision diodes linearly related to temperature changes, the current actual chip under test is calculated through a series of formulas temperature.

This means that if the temperature does not meet the standard, it will also be regarded as a defective product, which will also affect the yield of the final test, and due to the inaccuracy of the temperature, it will also cause some electrical test failures. Therefore, the temperature control problem in the final test of the semiconductor is beginning to be taken seriously.

Under normal circumstances, the low temperature test is -40 ℃, the upper and lower limits of the test program temperature test items are controlled at +/- 10 ℃, and more strictly +/- 5 ℃. In the manufacturing of semiconductors electronic components for harsh environments, the IC package assembly and test stages of engineering and production include burn-in, electronic hot and cold testing at temperature, and other environmental test simulations. These semiconductor devices and electronics, once put in real world applications, can get exposed to extreme environmental conditions.

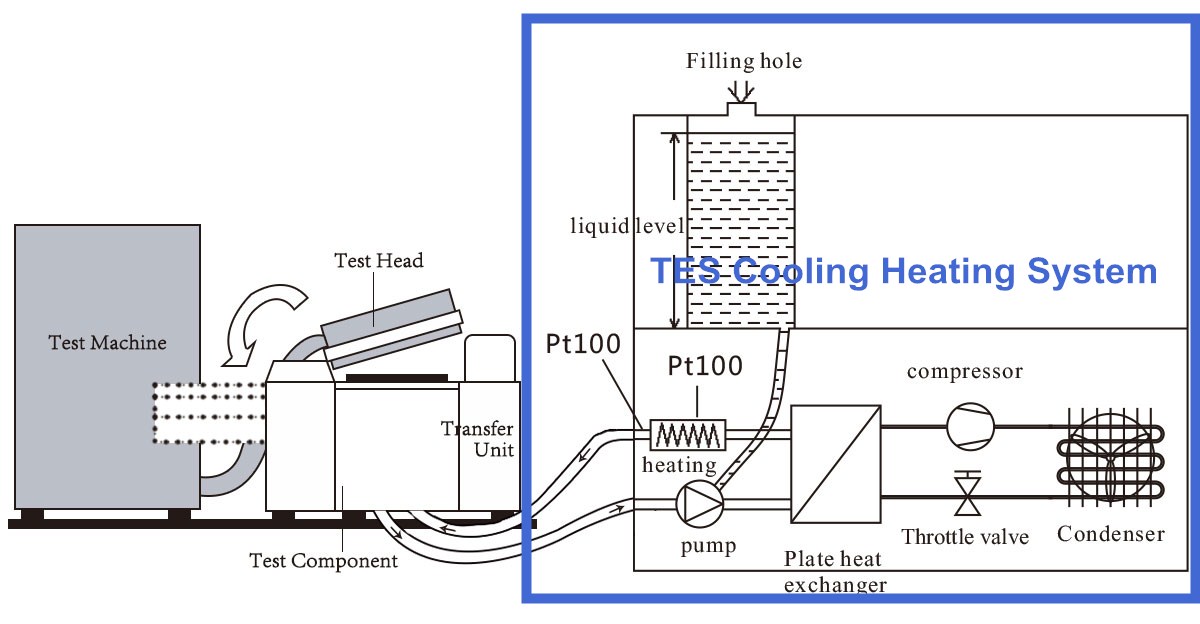

The LNEYA TES-85 has a temperature range from -80 ° C to + 225 ° C without the use of LN2 or CO2. Just connect the pipeline to the test area of the IC and other test benches, This lets you easily temperature test your electronic semiconductor IC devices.

Precision Temperature Forcing Systems use a direct temperature-controlled stream of hot or cold air to provide a precise thermal environment for temperature testing, conditioning and cycling of electronic and non-electronic assemblies and sub-systems. The ThermalAir Temperature System enables the test. This allows you to perform temperature simulation tests in situ, at a specific location, at your tester station, test bench or directly on the unit under test.

Bring temperature to your test for Semiconductor IC devices and other semiconductor packages. LNEYA TES series equipment temperature control range: -85 ° C ~ 200 ° C; power range: 2.5kW ~ 25kW; temperature control accuracy: ± 0.3 ° C. The pressure of the refrigeration system is realized by a pressure gauge (high pressure, low pressure); the pressure of the circulation system is detected by the pressure sensor and displayed on the touch operation screen. Refrigerant uses R404A R23 / R14 mixed refrigerant environmentally friendly refrigerant.

関連推奨品

-

Effect of Temperature on Reactions of Chemical Organic Synthesis

1300Organic synthesis is a common chemical phenomenon in chemistry. Temperature has an important influence on it during the whole synthesis process. As the temperature rises, the heat-absorbing reaction will speed up, resulting in a significant change...

詳細を見る -

LNEYA: Concentrate on designing every detail to create brilliant

1135LNEYA utilizes the outstanding talents in the field of refrigeration and heating temperature control, and has a strong technical background. It has a well-known high-end R&D team in the industry. It is a high-end R&D and application team f...

詳細を見る -

冷凍暖房温度制御システム燃料油試験指示書

1175冷凍の暖房の温度調整システムは操作の間に異なったプロジェクトのためにテストすることができる。異なるプロジェクトの検出は異なる。その中で、重油のテストのための冷凍の暖房の温度調整システムは ...

詳細を見る -

実験室における循環水チラーの選択の要点について語る。

947Circulating water cooler is also called chiller. It is a kind of cooling water equipment that can provide constant temperature, constant flow and constant pressure. Currently there are many kinds of chillers in the market. How to buy a suitable ch...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー