産業用冷凍機の性能を向上させる部品とは?

Industrial chillers are indispensable equipment in LNEYA production. With its normal operation, we will have better work efficiency and higher product quality. The refrigeration system of an industrial chiller is mainly composed of four core components: compressor, condenser, expansion valve and evaporator. On this basis, in order to improve the performance of industrial chillers, there are usually some auxiliary components.

(1) Compressors for industrial chillers:

It is the core of the entire chiller. Its quality is enough to affect the quality of a machine, and even the length of its lifespan. The compressor is the power source to ensure refrigeration. The compressor is used to increase the refrigeration pressure in the system, so that the refrigerant circulates in the refrigeration system to achieve the purpose of refrigeration. Common compressor types are open, semi-hermetic and fully-hermetic. Generally, the chiller with chilled water above 0°C adopts a fully hermetic compressor. If the chilled water is below 0°C, the low-temperature chiller uses a semi-hermetic compressor, while the open type is generally used in the refrigeration system with ammonia as the refrigerant.

(2) Condenser of industrial chiller:

It is the high temperature and high pressure Freon of the refrigeration system. After coming out of the compressor, it enters the condenser, releasing a lot of heat to the cooling medium, cooling and liquefying. There are three common types: water-cooled, air-cooled and evaporative. We mainly talk about water-cooled condensers. In a water-cooled condenser, the heat given off by the refrigerant is carried away by the cooling water. The cooling water can be flowed once or recycled. When using circulating water, cooling towers or cold pools are required. Water-cooled condensers have shell and tube, casing, immersion and other structural forms.

(3) Industrial chiller evaporator:

When the freon liquid in the refrigeration system enters the expansion valve and is sent to the evaporator, it belongs to the vaporization process. At this time, a large amount of heat needs to be absorbed, so that the temperature of the cooled medium is gradually lowered, so as to achieve the effect of cooling and cooling. According to the type of cooling medium, it is divided into two categories: cooling liquid (water) evaporator and cooling air evaporator.

(4) Industrial chiller expansion valve:

It is a throttling and pressure-reducing component that reduces the condensation pressure of the refrigerant to the evaporating pressure, so it is an essential component in the refrigeration system. It is called the four major components of the refrigeration system together with the compressor, the evaporator and the condenser.

関連推奨品

-

水冷チラーの冷却効果低下の原因分析

916水によって冷却されるスリラーは私達のまわりであらゆる人生の歩みでますます広く利用されている。その主な機能は、機器や製品に工業用冷水を供給することです。水温の範囲は、ユーザーのニーズに応じて調整することができます。

詳細を見る -

ロータリーエバポレーター用低温クーラント循環ポンプ

1279極低温冷却液循環ポンプの最大の最終消費市場は、化学および製薬分野である。この市場における低温冷却液循環ポンプへの需要の増加に伴い、極低温ポンプの用途は...

詳細を見る -

冷暖房サーモスタットの誤作動を防ぐには?

910ユーザーが冷暖房サーモスタットを作動させるとき、操作は指示に従う必要があるので、どのように不適切な操作を避けるか?冷暖房サーモスタットの優れた設計:LNEYA暖房と冷房サーモスタットは、マルチ...

詳細を見る -

冷暖房用サーキュレーターの不適切な運転を避けるには?

1033When the user runs the heating and cooling circulator, the operation needs to follow the instructions. Then, how to avoid unsuitable operation? LNEYA heating and cooling circulator has multi-function alarm system and safety function. It uses plate...

詳細を見る

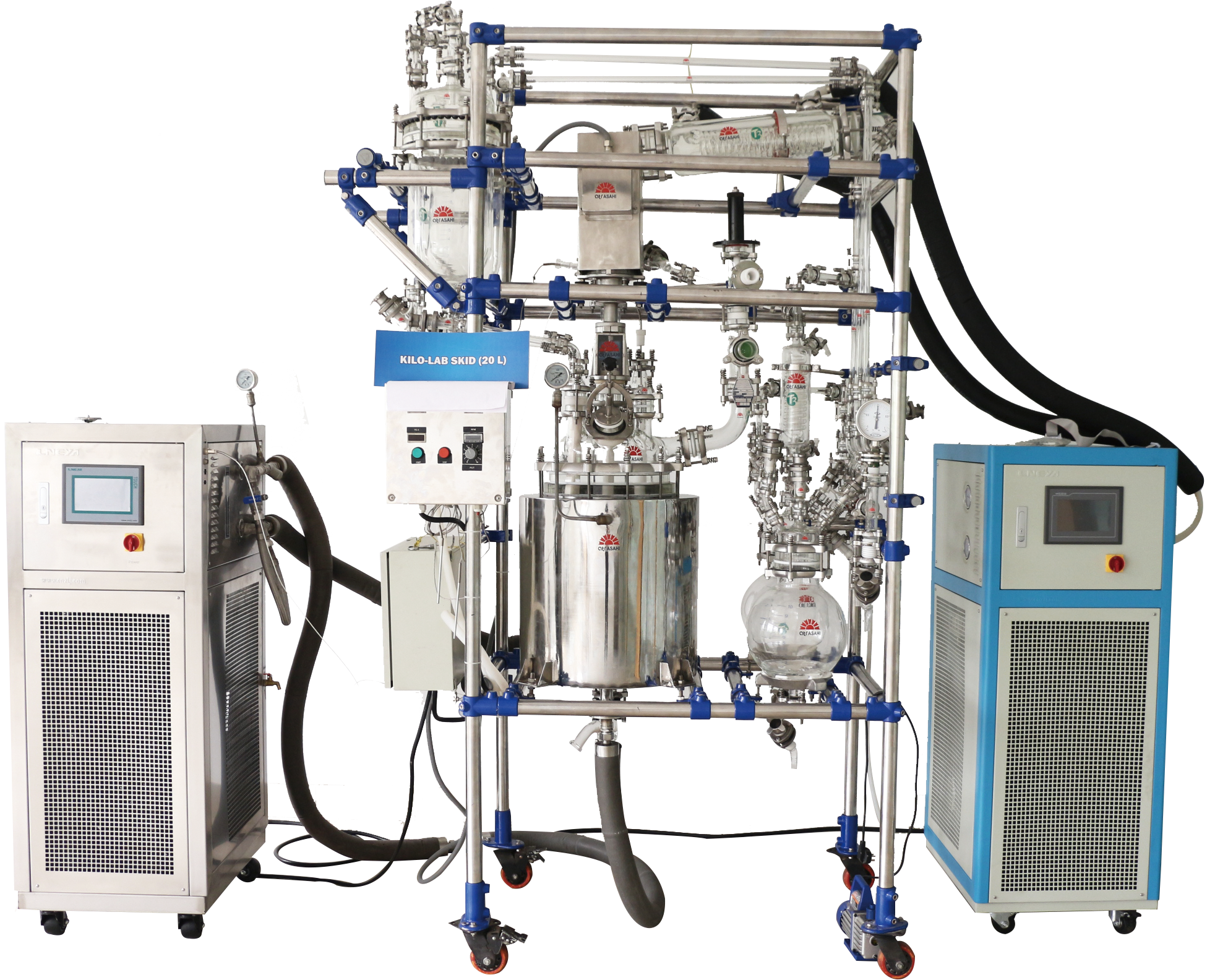

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー