最適なチラー・ソリューションを選ぶには?

Choosing a water chiller is like finding a “target” for an enterprise’s production equipment. It must not only be “like-minded”, but also “be well-matched”. The one that suits you is the best. If the choice is not good, either the cooling effect is not ideal, or energy is wasted, and other problems will appear.

First consider the actual situation of your own business, starting from six points:

1. The relationship between temperature difference and flow rate

How much material, how long does it take to cool down to how many degrees? In this way, the temperature difference of ice water required for cooling will be formed. The temperature difference of ice water is generally 3°C-5°C, but sometimes it may be 1°C-2°C. As far as the temperature difference is concerned, the smaller the temperature difference, the more ice water flow is needed to take away the same amount of heat, otherwise the less ice water flow is required.

2. Consider the solution with the least energy consumption

Energy consumption refers to electricity consumption. Especially when selecting a large industrial chiller, the comprehensive utilization and balance of electricity, heat and cold should be fully considered.

3. Refrigeration and stand-alone cooling capacity

The cooling capacity of the chiller is directly related to the energy consumption and operating economic effect of the whole unit, which is worth noting. For example, your production line requires stable and continuous refrigeration. Generally, there is no single chiller. When a chiller fails or is shut down for maintenance, other chillers are required to replace it. A reasonable number of units should be selected in combination with the production situation.

4. Are there any requirements for environmental protection?

There will be noise when the chiller is running, and the noise value will increase or decrease with the size of the chiller; some refrigerants used in chillers are toxic, pungent, flammable and explosive; some refrigerants will destroy the ozone layer in the atmosphere, When it reaches a certain level, it will pollute the air environment.

5. Cooling water quality requirements

The water quality of the cooling water will affect the cleanliness of the pipeline, especially the evaporator. Poor cooling water quality will accelerate the scaling and corrosion of the pipeline. This will not only affect the reduction of the cooling capacity of the industrial chiller, but also lead to replacement The heat pipe is clogged and damaged.

6. Explosion-proof and other special requirements

Chillers often work in harsh conditions and are often exposed to special substances such as flammable and explosive gases. When selecting a model, it is necessary to know whether the working environment of the chiller is an inflammable and explosive environment, whether it can be treated with explosion-proof treatment, and what is the explosion-proof level , and match the most suitable chiller scheme after comprehensive refrigeration demand.

The above are 6 considerations for choosing a chiller solution in the industry. You can also directly send the process temperature control requirements to sales@lneya.com. Our technical engineers will calculate the process parameters, determine the most suitable chiller model and send the equipment information and quotation to the customer.

関連推奨品

-

水冷式冷凍機の長所と短所

1082LNEYAが製造する水冷式工業用チラーは、冷水を供給する冷凍装置です。本日は、水冷式チラーの分類、メリット、デメリットについて説明する。水冷式冷凍機の構成1....

詳細を見る -

低温実験用特殊装置におけるエバポレーターの冷凍システムへの影響

1255低温実験専用機器は、LNEYAの実験室用冷凍加熱装置です。エバポレーターの重要性は自明である。では、蒸発器は冷凍システムにどのような影響を与えるのだろうか。その原理は、以下の通りである。

詳細を見る -

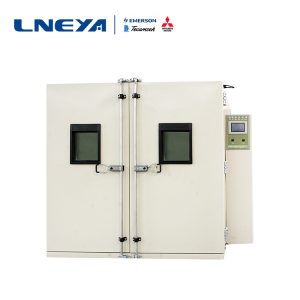

Step-by-step test box brand advantage description

1252The walk-in test box is developed and produced by LNEYA. It is specialized in pharmaceutical production technology and provides customers with various models of brands. Next, we will introduce the next step-in test box. Welcome to refer to and lea...

詳細を見る -

油圧による冷凍機コンプレッサーの故障

997冷凍制御系統に油圧がない場合、オイルポンプ配管系統の接続部に油漏れや詰まりがないか確認する。接続部が緩んでいる場合は、接続部を締める。閉塞している場合は、オイル配管を...

詳細を見る

LNEYA工業用冷凍機 メーカー サプライヤー

LNEYA工業用冷凍機 メーカー サプライヤー