冷却水循環装置の全モデル

LT 10℃~30℃

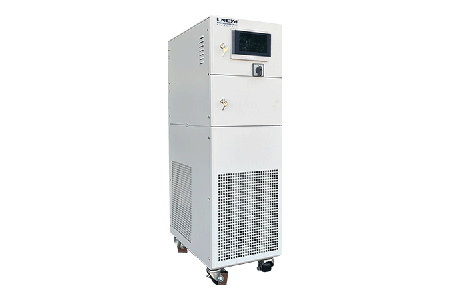

循環チラー

冷却能力 3kW~14kW

循環ポンプ流量 30L/分

(1.6bar~2bar)~50L/分(2bar)

LT -25℃~30℃

冷却サーキュレーター

冷却能力 1kW~5kW

循環ポンプ流量 30L/分 1.6bar

温度精度 ±0.5℃

LT -45℃~30℃

精密チラー

冷却能力 0.7kW~4.8kW

循環ポンプ流量 30L/分 1.6bar

温度精度 ±0.5℃

LT -60℃~-30℃

産業用チラー

冷却能力 0.7kW~4.8kW

循環ポンプ流量 30L/分 1.6bar

温度精度 ±0.5℃

LT -80℃~-40℃

冷水循環装置

冷却能力 0.4kW~2.5kW

循環ポンプ流量 30L/分 1.6bar

温度精度 ±0.5℃

LT-800 -18~30℃

小型チラー

冷却能力 0.35kW~0.9kW

循環ポンプ流量 10L/分 0.6bar

LNEYAサーモ冷凍株式会社

LNEYAサーモ冷凍株式会社